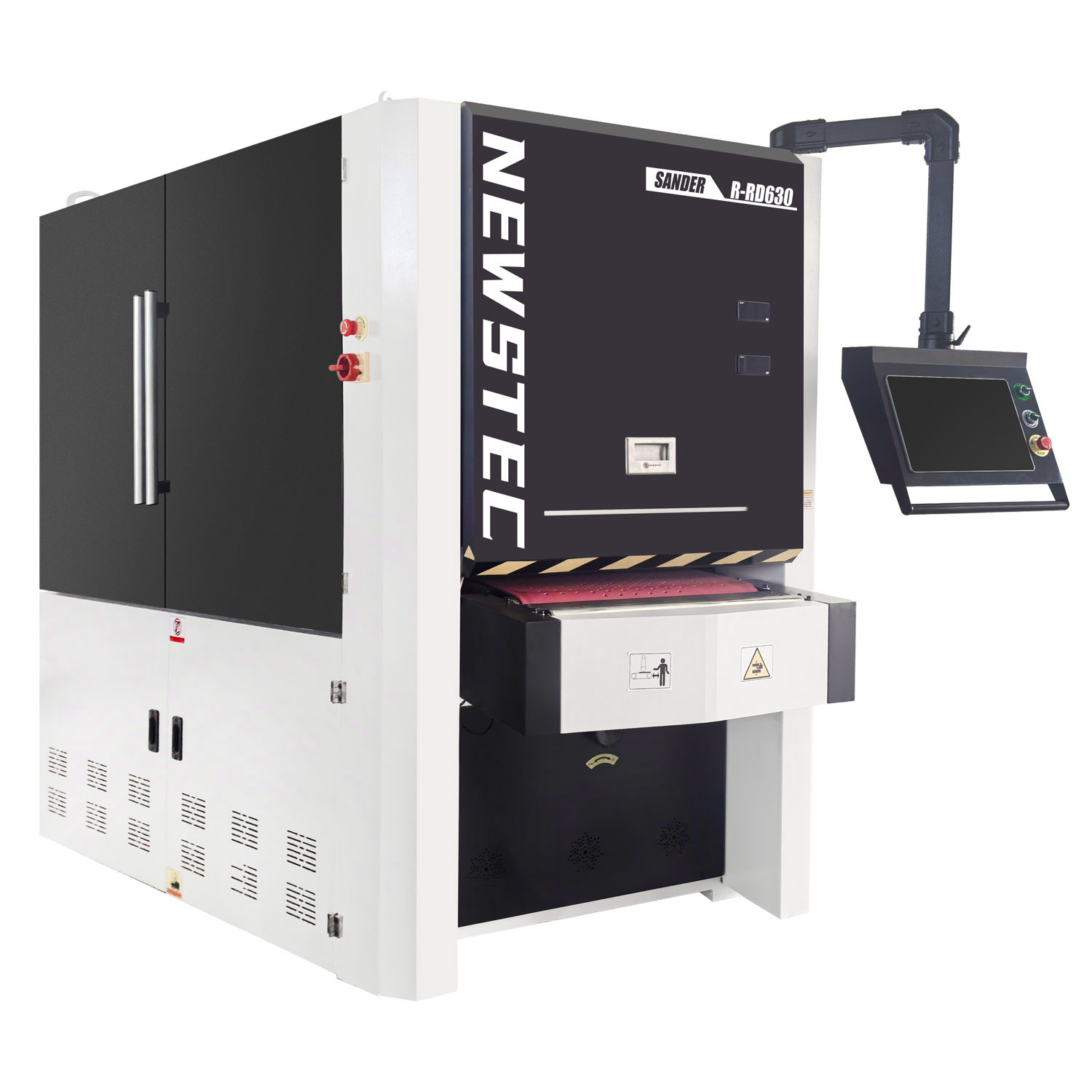

R-RD630 Small Metal Sheet Deburring and Chamfering Machine

01020304

Parameters

|

Working width(mm) |

800 |

|

Min.Working length(mm) |

300 |

|

Working thickness(mm) |

0-100 |

|

Abrasive belt motor(kw) |

11KW |

|

Rotary brush motor power(kw) |

1.5kwX2 |

|

Total Power |

28kw |

|

Transmission motor power(kw) |

4 |

|

Lift motor power |

0.55 |

|

No.1 unit of belt shelf |

210mm |

|

Adsorption |

11kw 2900RPM |

|

Controller system |

Delta PLC |

|

Rotary brush size(mm) |

300x300x25 |

|

Rotary brush quantity |

4 |

|

Voltage |

220v/380V3PH |

|

Power |

50/60HZ |

|

Abrasive belt size(mm) |

650*1900mm |

|

Overall dimensions(mm) |

Machine :2700*1500*2000mm |

|

Gross Weight(with wooden case)(kg) |

3200KGS |

product description

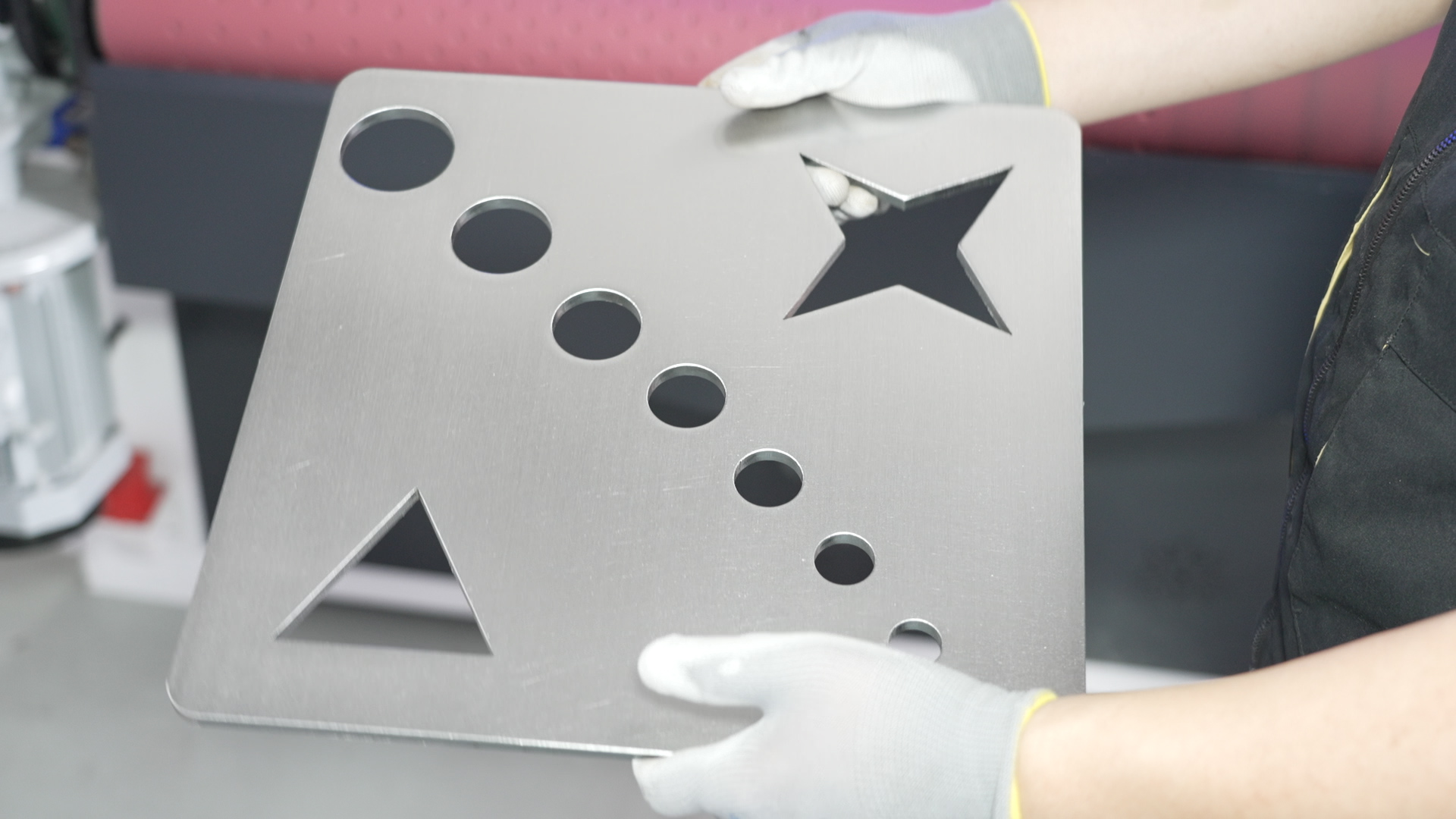

It improves production efficiency and safety. Traditional manual deburring processes are inefficient, labor-intensive, and inconsistent. Using automated deburring machines not only significantly improves processing efficiency but also ensures uniform processing quality. Furthermore, the equipment is safe and reliable to operate, preventing workers from being cut by sharp burrs.

Deburring machines are widely used in industries such as automotive manufacturing, aerospace, electronics, medical devices, and machinery manufacturing.

Metal deburring machines play a vital role in modern metal processing. They not only improve the quality and precision of parts but also enhance the production environment, efficiency, and safety. As the manufacturing industry continues to demand higher precision and surface quality, the automation and intelligence of deburring machines are constantly evolving, making them an indispensable piece of equipment in modern metal processing production lines.

Deburring machines are widely used in industries such as automotive manufacturing, aerospace, electronics, medical devices, and machinery manufacturing.

Metal deburring machines play a vital role in modern metal processing. They not only improve the quality and precision of parts but also enhance the production environment, efficiency, and safety. As the manufacturing industry continues to demand higher precision and surface quality, the automation and intelligence of deburring machines are constantly evolving, making them an indispensable piece of equipment in modern metal processing production lines.

-

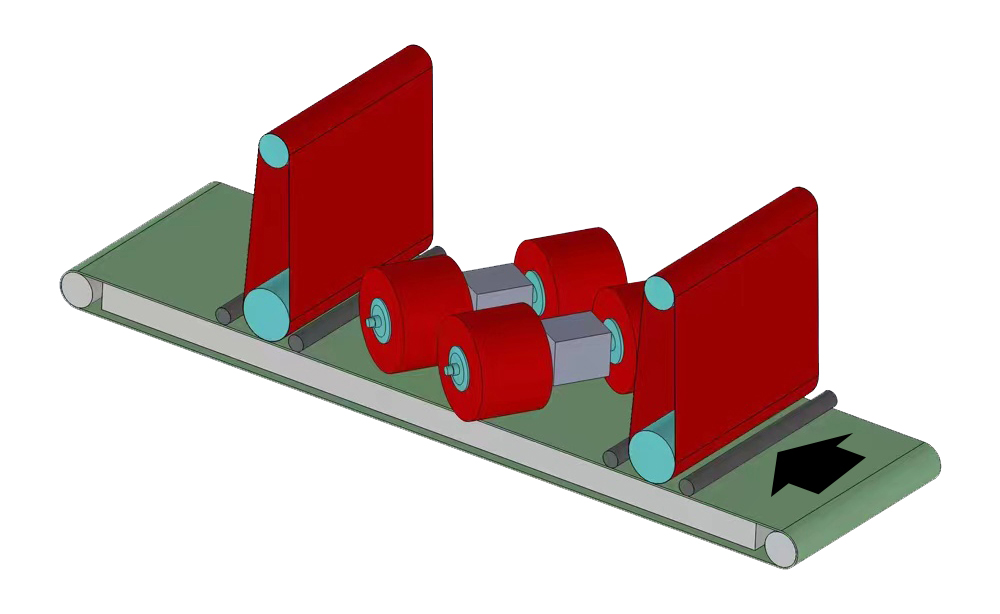

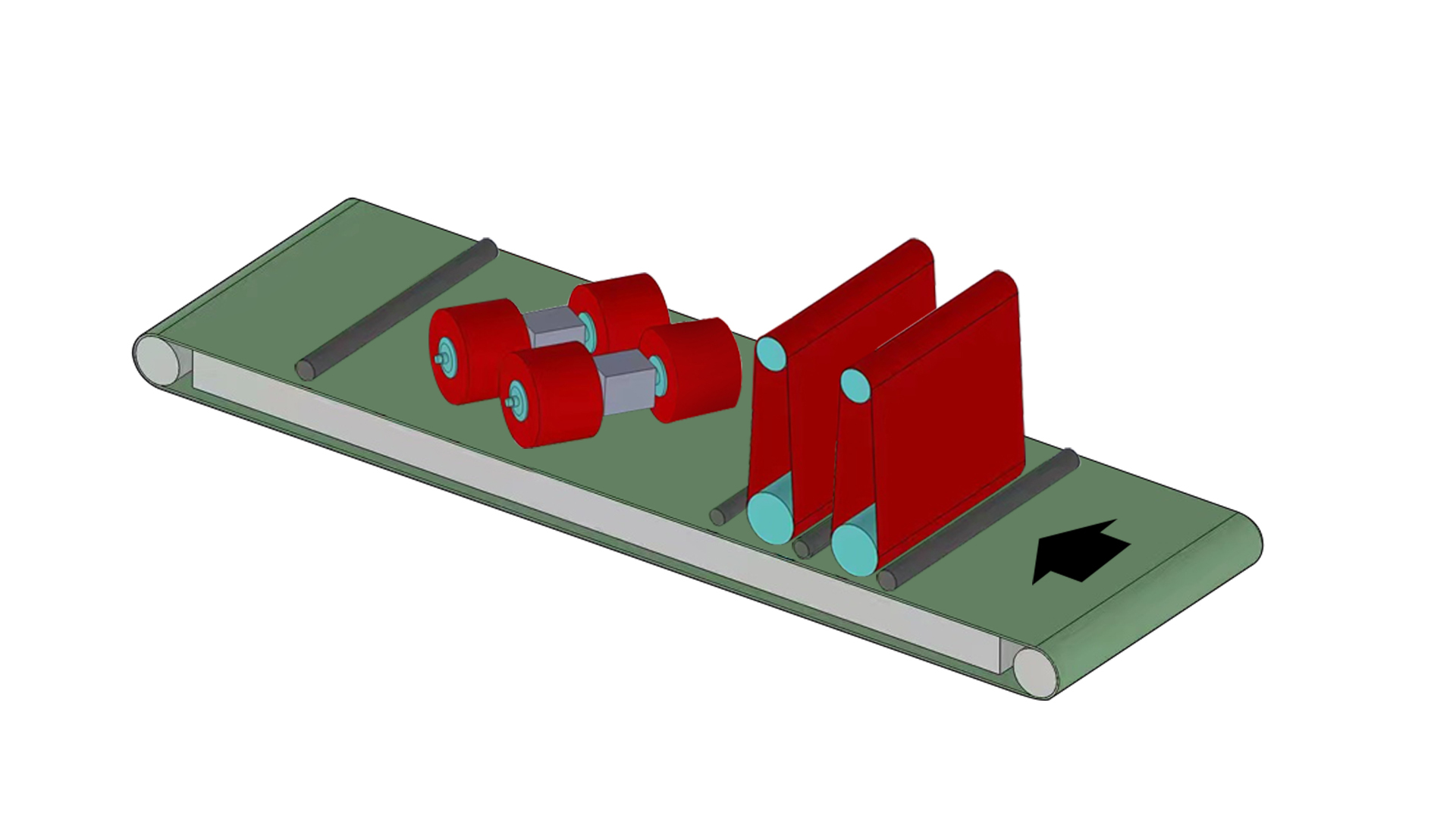

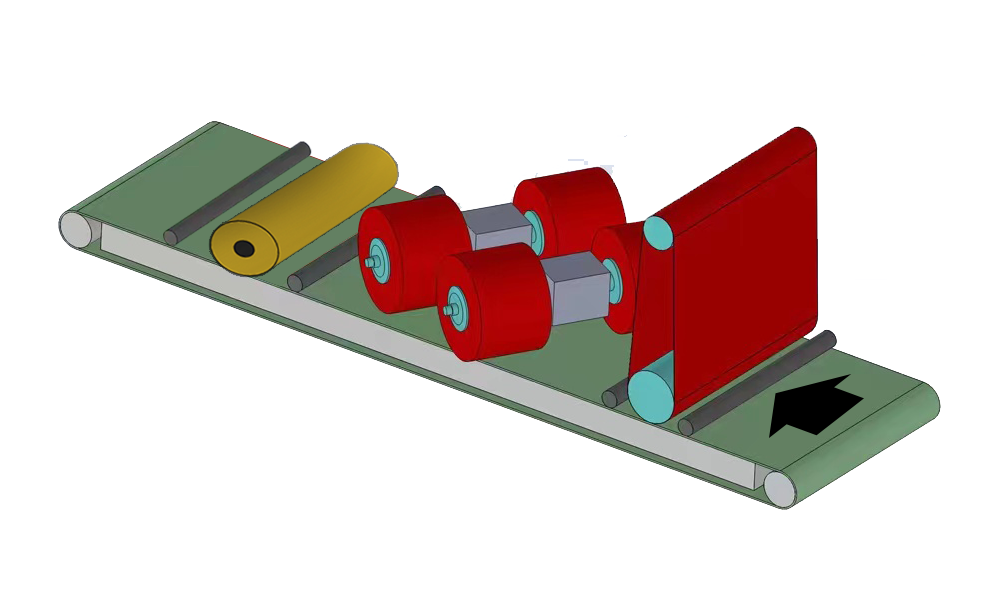

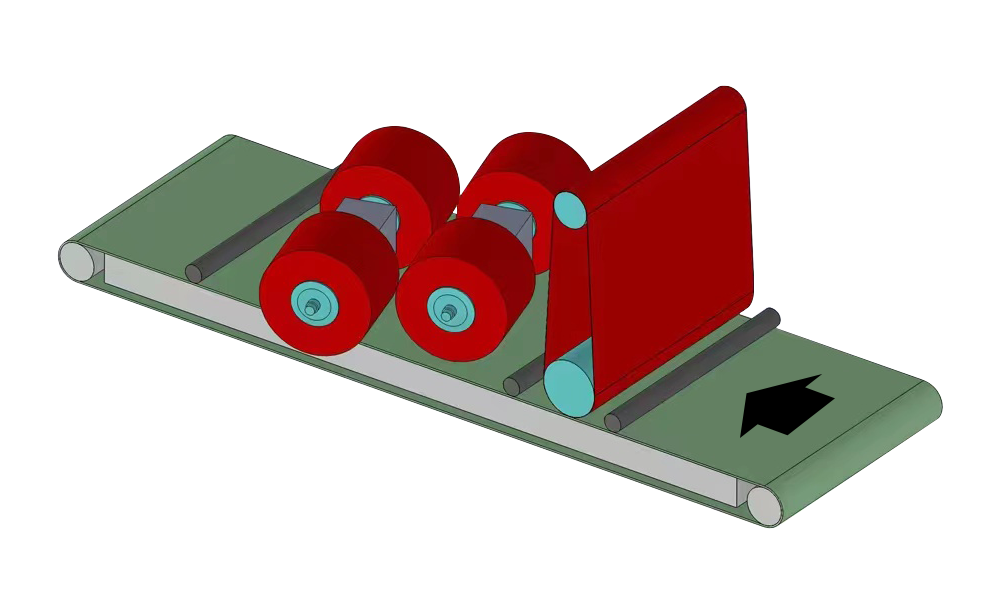

UNIT STRUCTURE

Each unit is independently

controlled and can be

combined as needed.

-

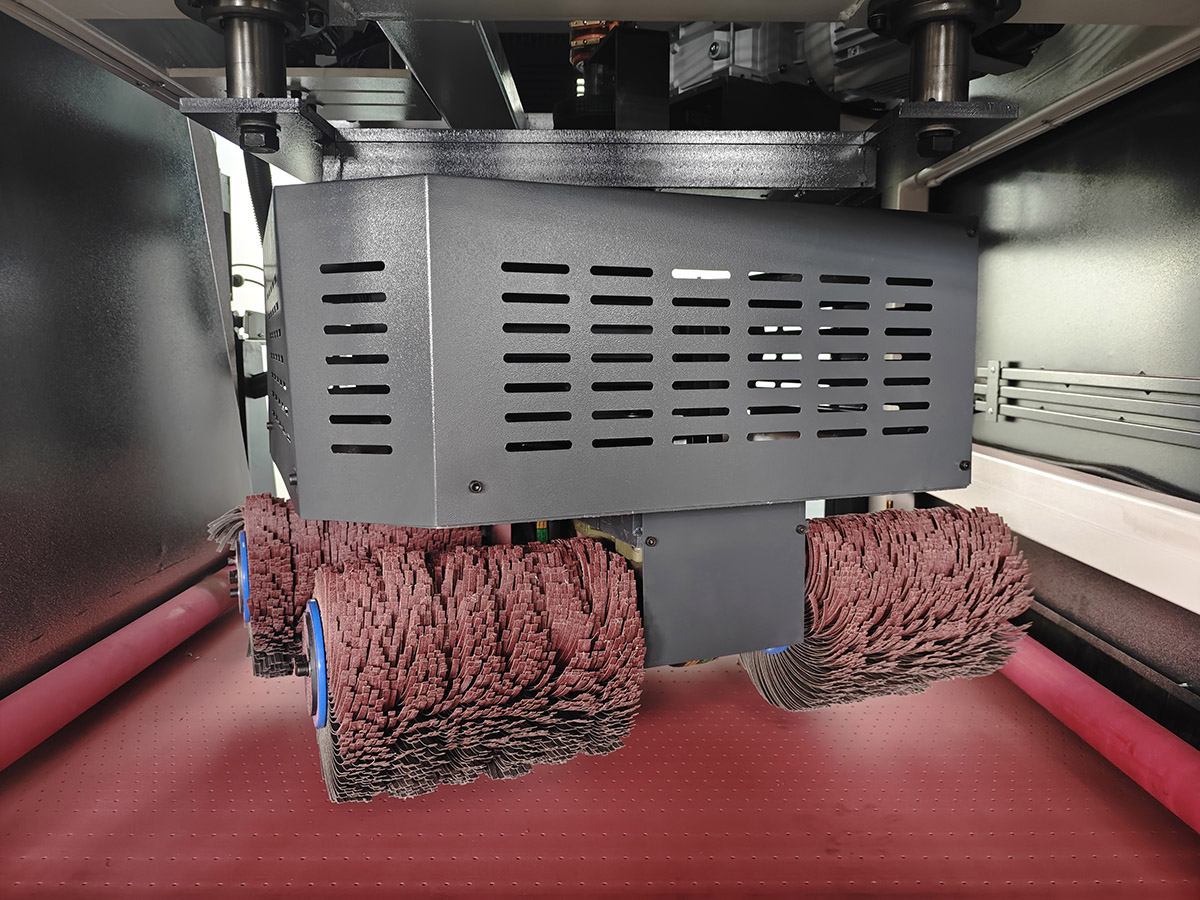

ROTARY

Deburring, chamfering and

finishing of internal and

external contours.

-

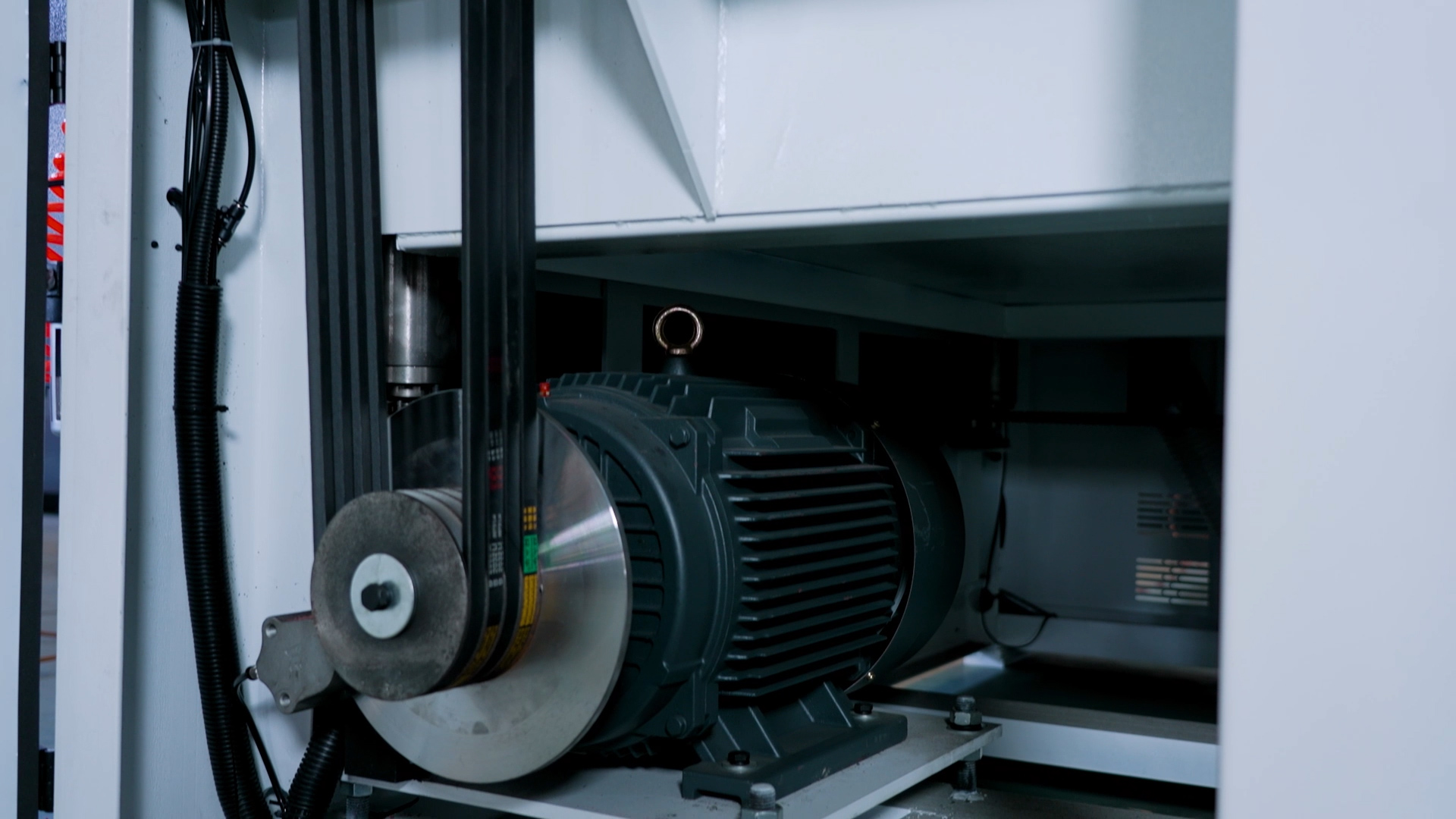

MOTOR

Copper core motor, stable and durable, long service Ife.

-

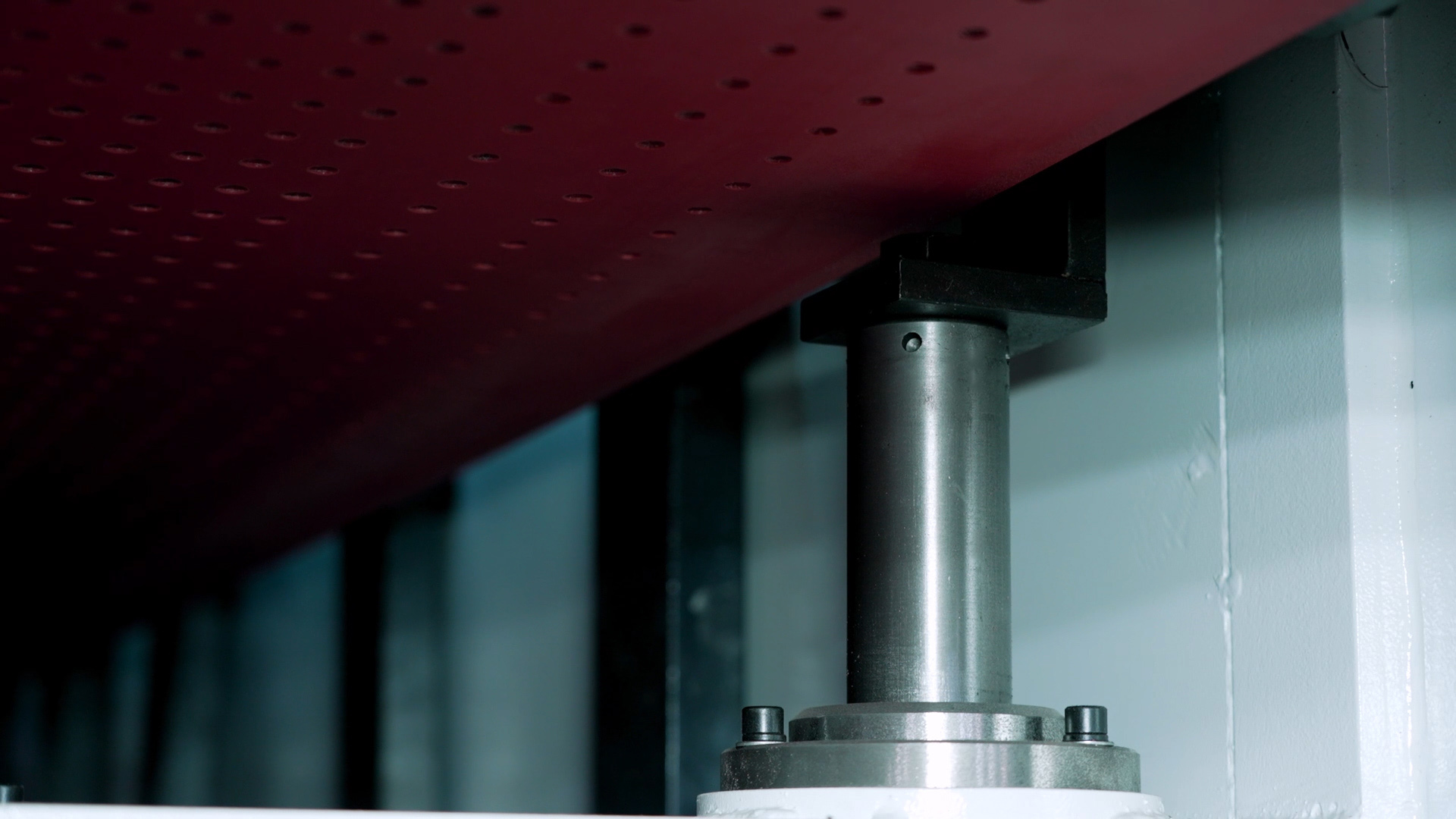

PLATFORM LIFTING

0-100mm lifting platform precise lifting, high stability and large load-bearing capacity.