Why do metal sheets need to be deburred and chamfered?

After metal Sheets are processed (such as cutting, stamping, milling, etc.), burrs or sharp edges often appear on the edges. Deburring and chamfering are important subsequent processing procedures. Their core purpose is to improve product quality, safety, performance and adaptability to subsequent processing. The specific reasons are as follows:

1. Ensure operational safety and avoid personal injury

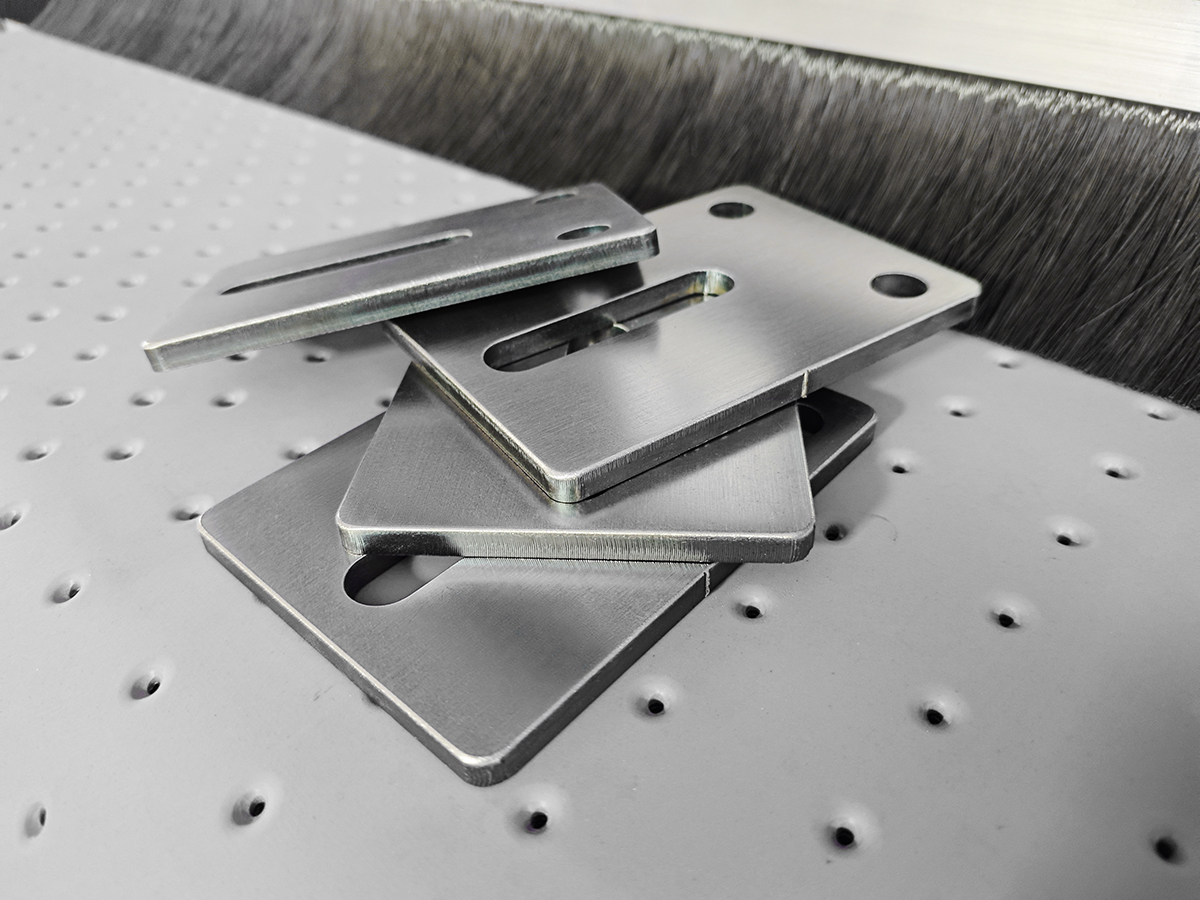

Necessity of removing burrs: There may be fine burrs (such as metal debris, raised sharp edges) on the edges of processed metal Sheets. These burrs are hard and have sharp edges. Operators are easily scratched during handling, assembly or use, leading to safety accidents.

The role of chamfering: Chamfering sharp right-angle edges into rounded or beveled corners can prevent people from being "cut" when in contact, especially for plates that require manual assembly or daily use (such as home appliance housings, mechanical equipment panels), safety is the primary consideration.

2. Improve product quality and aesthetics

Eliminate appearance defects: Burrs and sharp edges are processing defects that affect the overall appearance of the product. For example, products with high requirements for appearance, such as automobile body panels and electronic equipment housings, must be deburred and chamfered to ensure that the edges are flat and smooth and meet the appearance standards.

Avoid local stress concentration: Sharp right-angle edges are prone to stress concentration when subjected to force, and long-term use may cause cracking or deformation of the edges of the panels. After chamfering, the stress distribution is more uniform, which can improve the structural stability and service life of the product.

3. Ensure the accuracy of subsequent processing and assembly

Facilitate assembly and coordination: If there are burrs on the edge of the Sheet, when assembling with other parts (such as welding, riveting, and bolting), the burrs may cause the parts to not fit tightly, resulting in gaps or positioning deviations, affecting the assembly accuracy. For example, if there are burrs at the joints of mechanical parts, the overall size may be out of tolerance after assembly.

Adapt to subsequent processing procedures: Before surface treatment such as painting and electroplating, burrs will affect the uniformity of the coating (such as the coating accumulating or falling off at the burrs); in CNC machining, burrs may interfere with the tool path and cause machining errors. After deburring, it can ensure the smooth progress of subsequent processes.

4. Protect equipment and other parts

Avoid damage to related parts: When a plate with burrs moves or contacts other parts (such as metal plates and pipe interfaces in mechanical transmission), the burrs may scratch the surface of adjacent parts (such as seals, rubber parts, and the inner wall of precision instruments), causing component wear, leakage, or functional failure. For example, if there are burrs on the metal plate in the hydraulic system, it may scratch the inner wall of the oil pipe, causing hydraulic oil contamination or pressure loss.

Reduce equipment wear: In an automated production line, a plate with burrs may get stuck in the conveying device (such as a conveyor belt, a manipulator), causing equipment shutdown or damage, and increasing maintenance costs.

5. Comply with industry standards and specifications

Many industries (such as aerospace, medical devices, and automobile manufacturing) have strict standards for the edge quality of metal plates, and explicitly require the removal of burrs and chamfering.

Deburring and chamfering of metal plates is a key process that takes into account safety, quality, performance, and process adaptability. It can not only avoid personal injury and equipment loss, but also ensure the accuracy, life, and compliance of the product. It is an indispensable part of metal processing.