Why deburring machines are needed

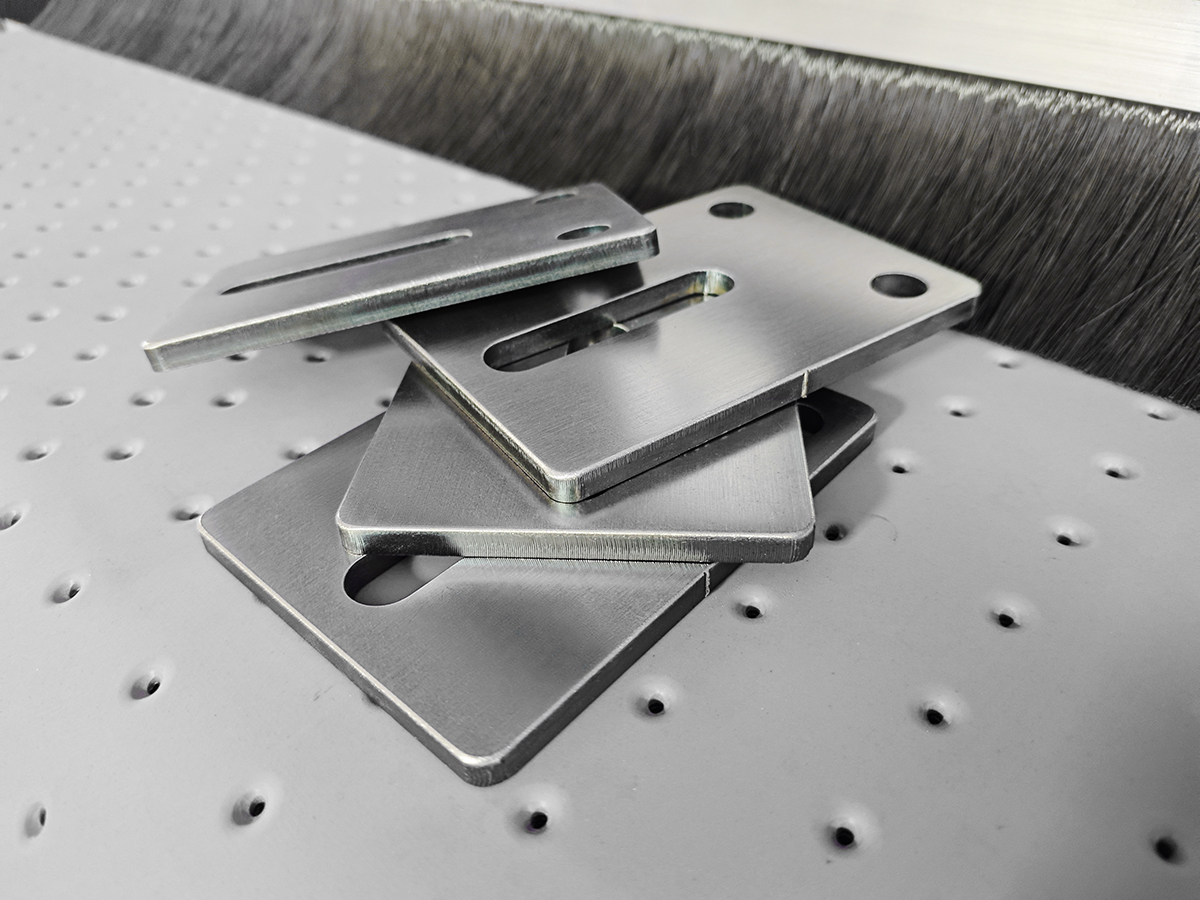

Burrs often appear during processes such as cutting, stamping or machining, creating unwanted protrusions that can disrupt product functionality or cause safety issues. These defects not only affect assembly accuracy, but also increase the risk of unqualified parts. To ensure consistent quality, manufacturers include deburring as a necessary stage in the production cycle.

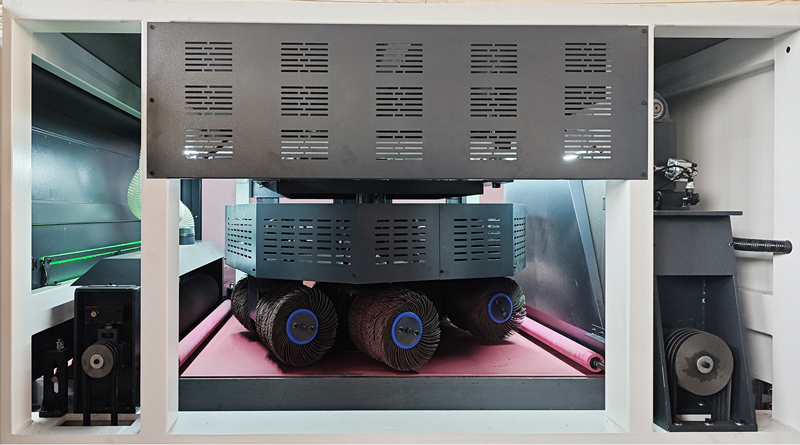

NEWSTEC deburring Machines are carefully designed to remove burrs, sharp edges and slag from workpieces after machining, while also rounding edges for safer handling and consistent part quality.

NEWSTEC deburring Machines are typically configured in a multi-station configuration, enabling them to perform deburring, edge rounding and oxide layer removal simultaneously. These integrated systems typically include dust removal devices to maintain a clean working environment, automatic feed conveyors for smooth part handling, and pressure-regulating sensors for optimal tool contact. This design ensures reliable, safe and efficient operation even when handling large production runs.

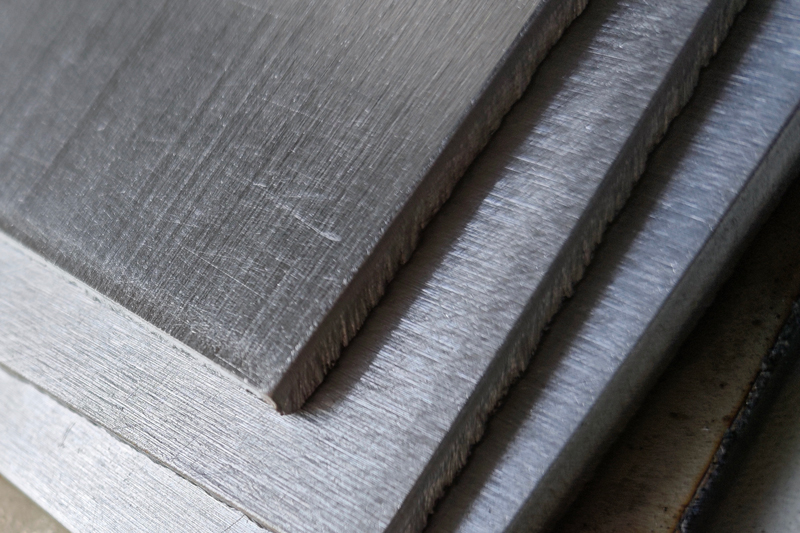

After deburring and polishing, the dimensional accuracy of the workpiece does not change, there is no bumping in the Deburring Machine, the precision of the thrown parts is high, the geometric dimensional accuracy does not change, and the workpiece surface can be mirror-bright after fine polishing.

The appearance and feel are significantly improved, which is a polishing effect that cannot be achieved by some manual polishing or imported Polishing Equipment. It completely replaces the backward traditional polishing process and greatly improves the polishing efficiency and benefits.

Suitable for flat plate parts, carbon steel plates, stainless steel plates, aluminum plates, copper plates, titanium alloys, various non-ferrous metals, rubber and plastic materials, etc.