The best solution for grinding aluminum plates

Wet sanding is an efficient and high-quality processing method for aluminum plates, especially suitable for scenes with high requirements for surface finish, precision and environmental protection. Combined with the material characteristics of aluminum plates (soft texture, easy to oxidize, sensitive to high temperature), the advantages of Wet Sanding Machines can be fully utilized, but some operating details should also be noted. The following is a specific analysis:

1. The core advantages of wet sanding for aluminum plates

Improve surface finish and reduce scratch defects

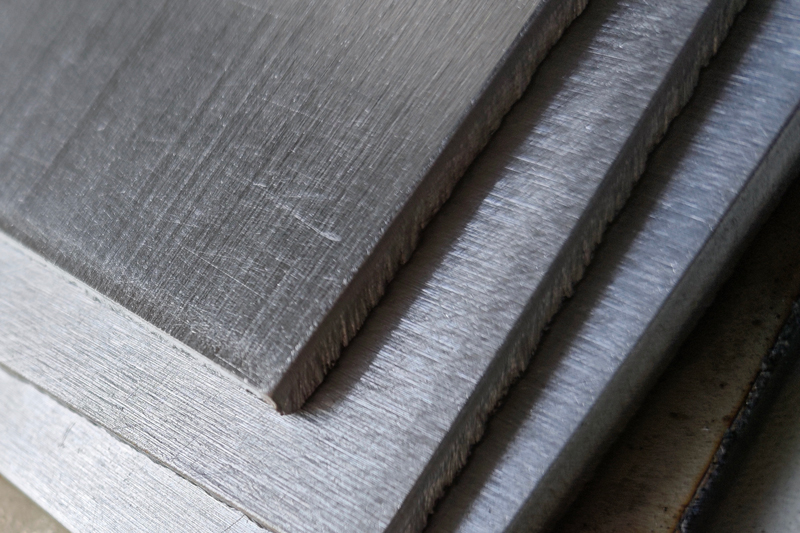

The texture of aluminum plates is relatively soft, and the aluminum chips generated during dry sanding are easy to adhere to the surface of sandpaper, resulting in secondary scratches or "pulling" (irregular scratches on the surface). Wet sanding uses water to flush aluminum chips and abrasive particles in real time to avoid impurities and significantly reduce surface roughness. It is especially suitable for:

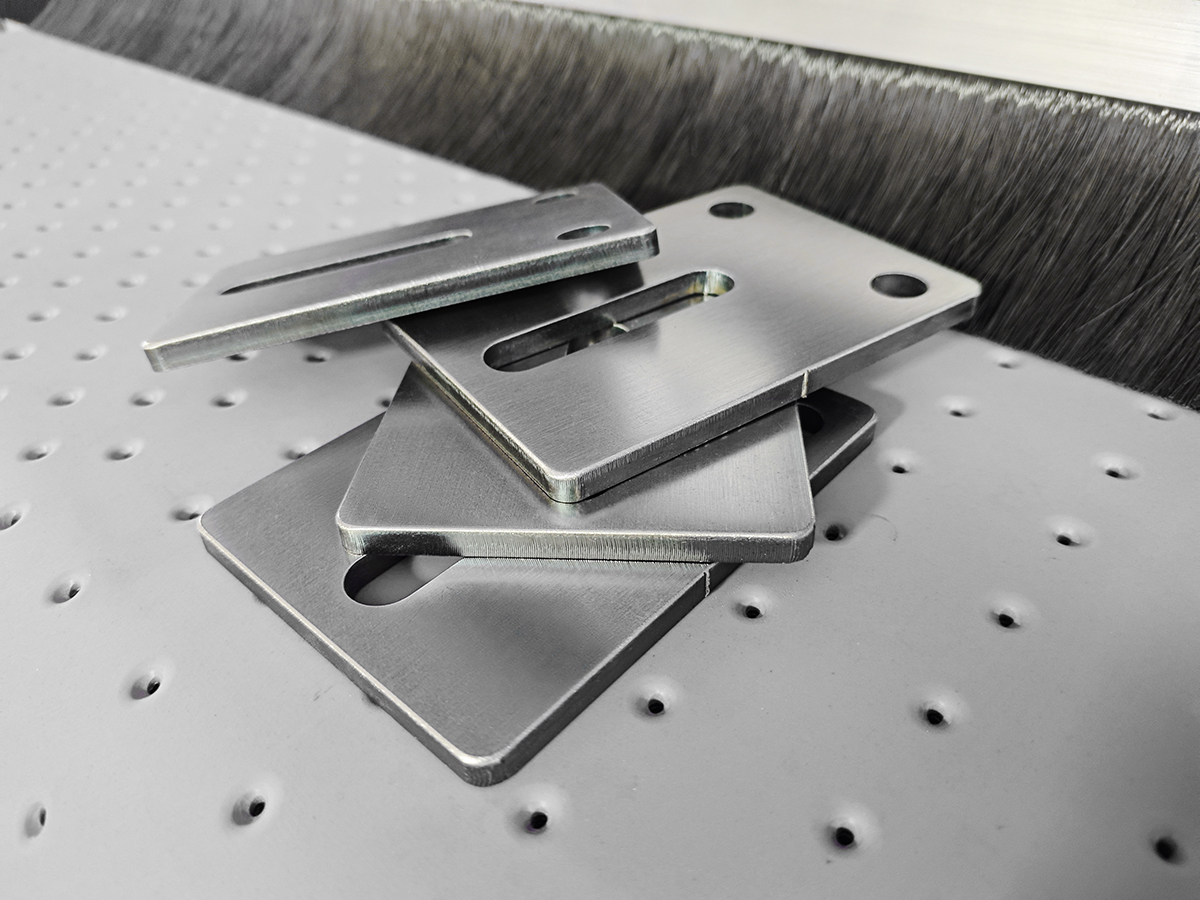

Surface pretreatment of precision parts (such as aerospace aluminum plate components);

Priming and polishing before aluminum plate painting and anodizing (to ensure uniform coating adhesion);

Mirror effect processing (such as decorative aluminum plates and instrument panels).

Avoid oxidation and high temperature damage

Aluminum plates are easily oxidized to form oxide films (Al₂O₃) when exposed to air. The high friction temperature of dry sanding will accelerate oxidation, and the oxide film is hard, which may cause rapid wear of sandpaper or "hard spots" on the surface (uneven local grinding).

The cooling effect of wet sanding can:

Control the temperature of the workpiece (usually below 50℃) and reduce the oxidation reaction rate;

The water flow can wash away the surface oxide layer debris to prevent it from interfering with subsequent grinding and ensure the purity of the aluminum plate matrix.

Reduce dust hazards and improve operational safety

Aluminum dust is a combustible dust (it may explode when exposed to open flames when the concentration reaches a certain value), and long-term inhalation can cause "aluminum pneumoconiosis" (pulmonary fibrosis disease). Wet sanding mixes aluminum dust with water to form slurry, completely eliminating the risk of dust dispersion, and is particularly suitable for:

Enclosed workshops or indoor processing (such as auto parts factories, home appliance production workshops);

Scenarios with strict environmental protection requirements (such as processing of aluminum plates for food contact to avoid dust pollution).

Extending abrasive life and reducing consumable costs

Dry sanding can cause aluminum chips to clog the sandpaper pores (especially fine-grit sandpaper, such as 400 grit and above), resulting in reduced sanding efficiency and frequent paper changes. The water flow of wet sanding continuously cleans the sandpaper surface, reducing clogging and extending the life of the sandpaper (or belt) by 30%-50%. This is especially cost-effective for high-cost precision abrasives such as silicon carbide sandpaper.

While dry sanding requires additional wastewater treatment (requiring filtration and recovery of aluminum chips and water), it remains the preferred solution for fine aluminum Sheet processing, considering surface quality, material protection, and operational safety.