Sheet metal chamfering machine

2025-08-14

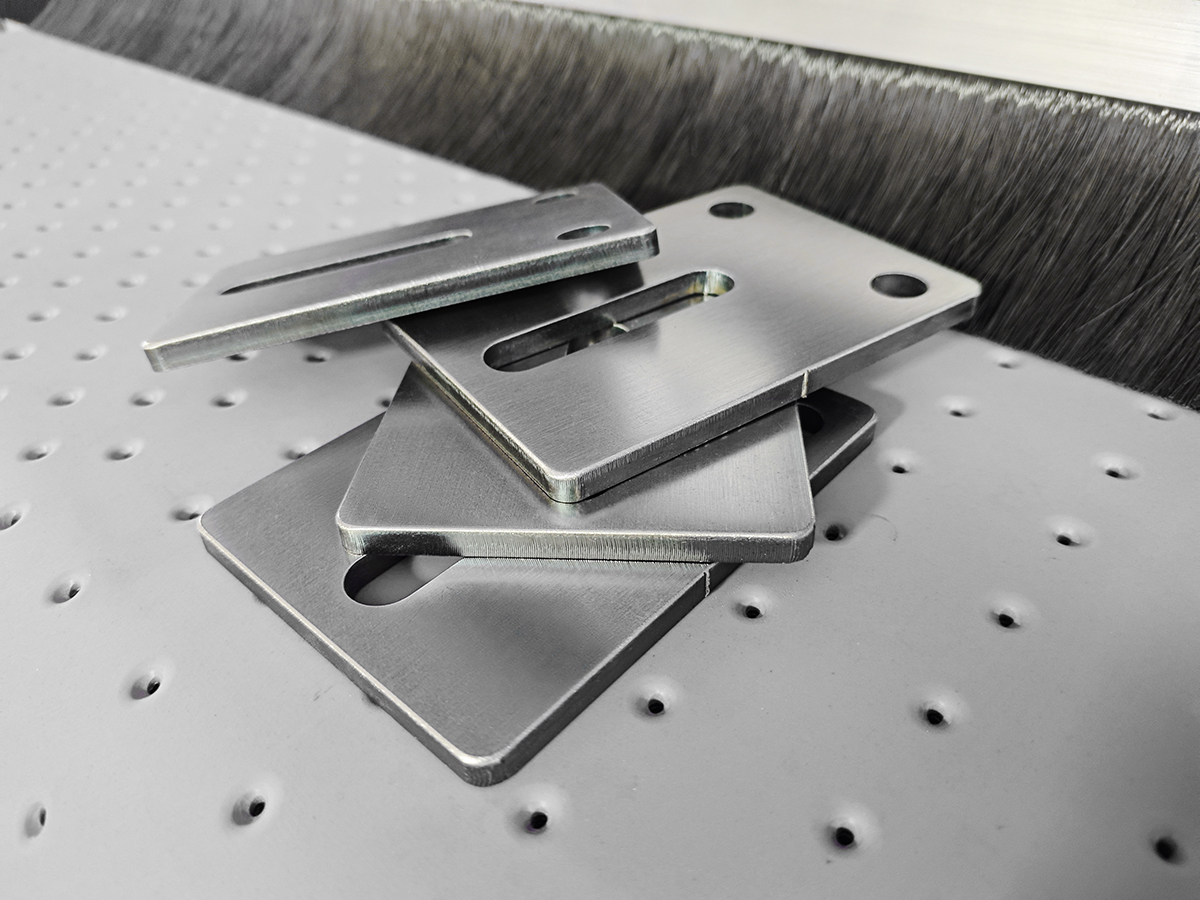

A chamfering machine is a precision machine used in mold manufacturing, hardware machinery, machine tool manufacturing, hydraulic parts, valve manufacturing, textile machinery, and other fields. It is primarily used to chamfer workpiece edges and remove burrs caused by milling and planing processes.

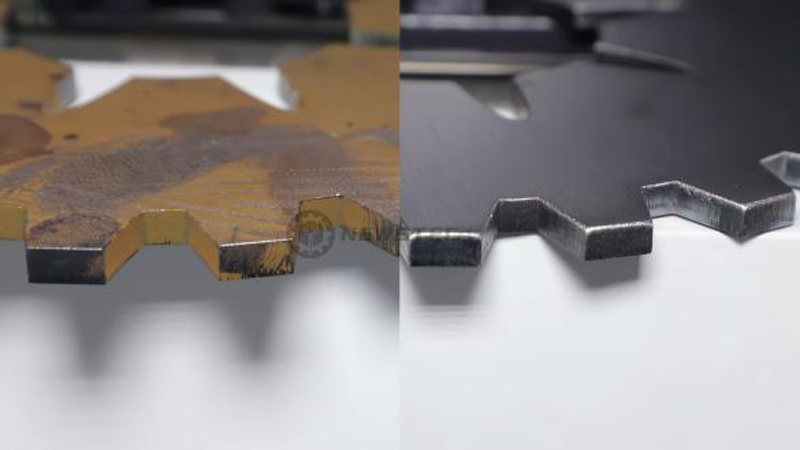

Universal roller brushes are used for metal chamfering and deburring.

Multiple sets of universal roller brushes rotate and revolve, ensuring full contact with the workpiece. They are used for deburring corners, rounding corners, chamfering rounded corners, deburring, and smoothing edges.

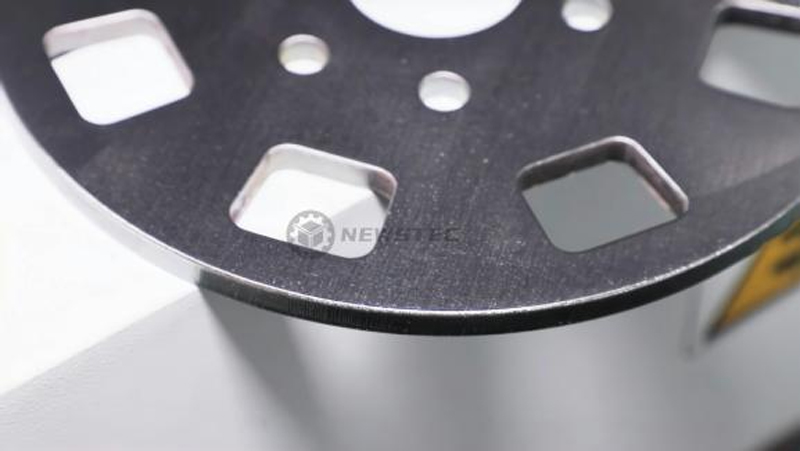

• Removes light/soft burrs on contour edges

• Uniformly rounds internal and external contours

The grinding unit consists of 4/6/8 roller brushes arranged in parallel. The alternating rotation and self-rotation of the roller brushes allow the abrasive belt to grind the workpiece without dead angles, achieving both deburring and rounding.

Applications: • Burrs and sharp edges resulting from cold working processes such as stamping and shearing

• Soft burrs resulting from laser Sheet cutting

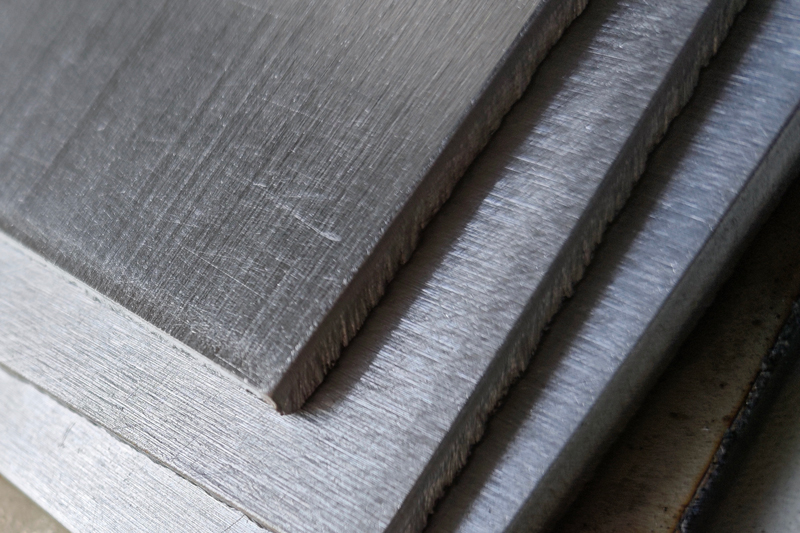

Applicable Materials: Stainless steel, iron, copper, aluminum, alloys, and other metal Sheets, as well as coated Sheets

Applications: Removes burrs from laser-cut, water jet-cut, and stamped products.

Application Industries: Metal polishing and deburring Machines are widely used in the manufacture of billboards, signs, advertisements, metal letters, LED letters, kitchenware, advertising letters, sheet metal fabrication, metal parts, ironware, computer cases, cabinet processing, metal crafts, elevator panels, hardware, auto parts, eyeglass frames, electronic components, nameplates, and more.