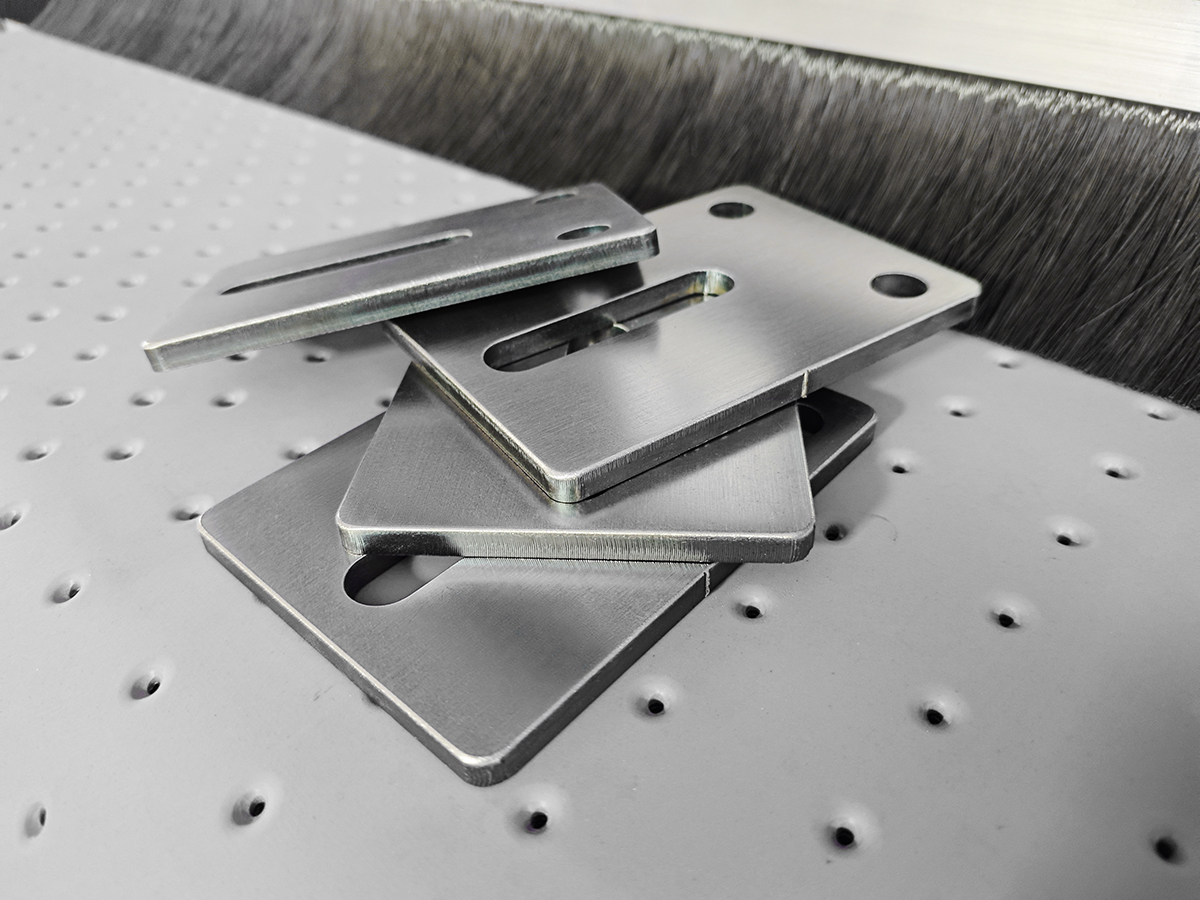

Metal deburring polishing machine

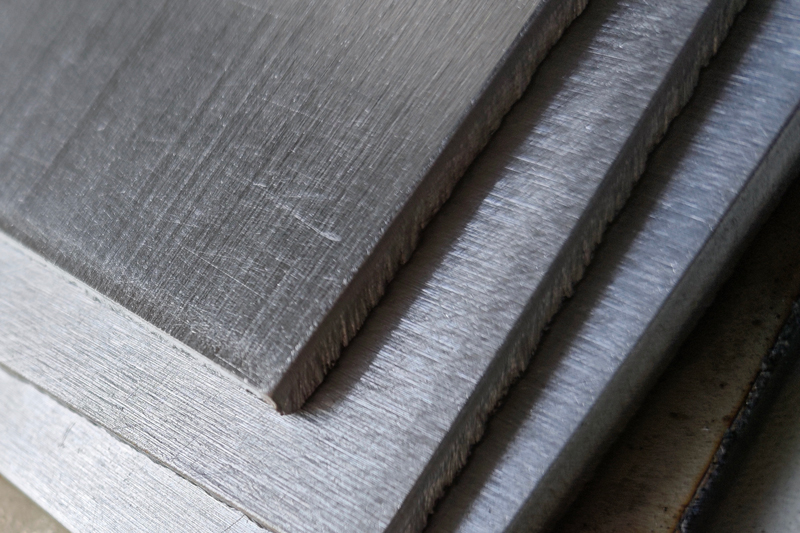

We specialize in deburring, chamfering, deburring and chamfering, rust removal, rust removal, processing knife marks, precision polishing, mirror polishing and other services for small and medium-sized parts made of various metal and non-metal materials. We use internationally leading processing technology and equipment to develop exclusive processing solutions based on the characteristics of different materials. Taking metal materials as an example, for alloy steel parts with higher hardness, we use special high-strength grinding materials and precise CNC processing technology to ensure that the deburring process is efficient and does not damage the part matrix.

In terms of technology, our process has excellent stability. The workpiece will not bulge during the polishing process, nor will it change the dimensional accuracy of the workpiece. Ensure that every polishing can achieve the ideal effect. In addition, we can also professionally design and customize special Polishing Machines according to user needs, from the size specifications and processing capacity of the equipment to the degree of automation, operation interface and other aspects to meet the personalized needs of customers in all aspects.

The use and advantages of polishing machines: Our polishing machines are widely used in deburring, flash removal, chamfering, rust removal, descaling, electroplating pre-treatment, removal of processing knife marks and bright polishing of workpiece surfaces. The biggest advantage of the Deburring Machine: after deburring and polishing, the dimensional accuracy of the workpiece remains unchanged. After fine polishing, the surface of the workpiece can reach a mirror-like brightness, and even extremely small flaws can be perfectly eliminated.

Through actual application, customers have reported that the appearance and texture of the product have been significantly improved. This polishing effect cannot be achieved by some manual polishing or imported Polishing Equipment. Our technology and equipment have completely replaced the backward traditional polishing process. For example, after a certain machinery manufacturing company introduced our Polishing Equipment, its polishing efficiency increased by 3 times, production costs decreased by 40%, and economic benefits were greatly improved.