How to deal with the dust generated in metal grinding?

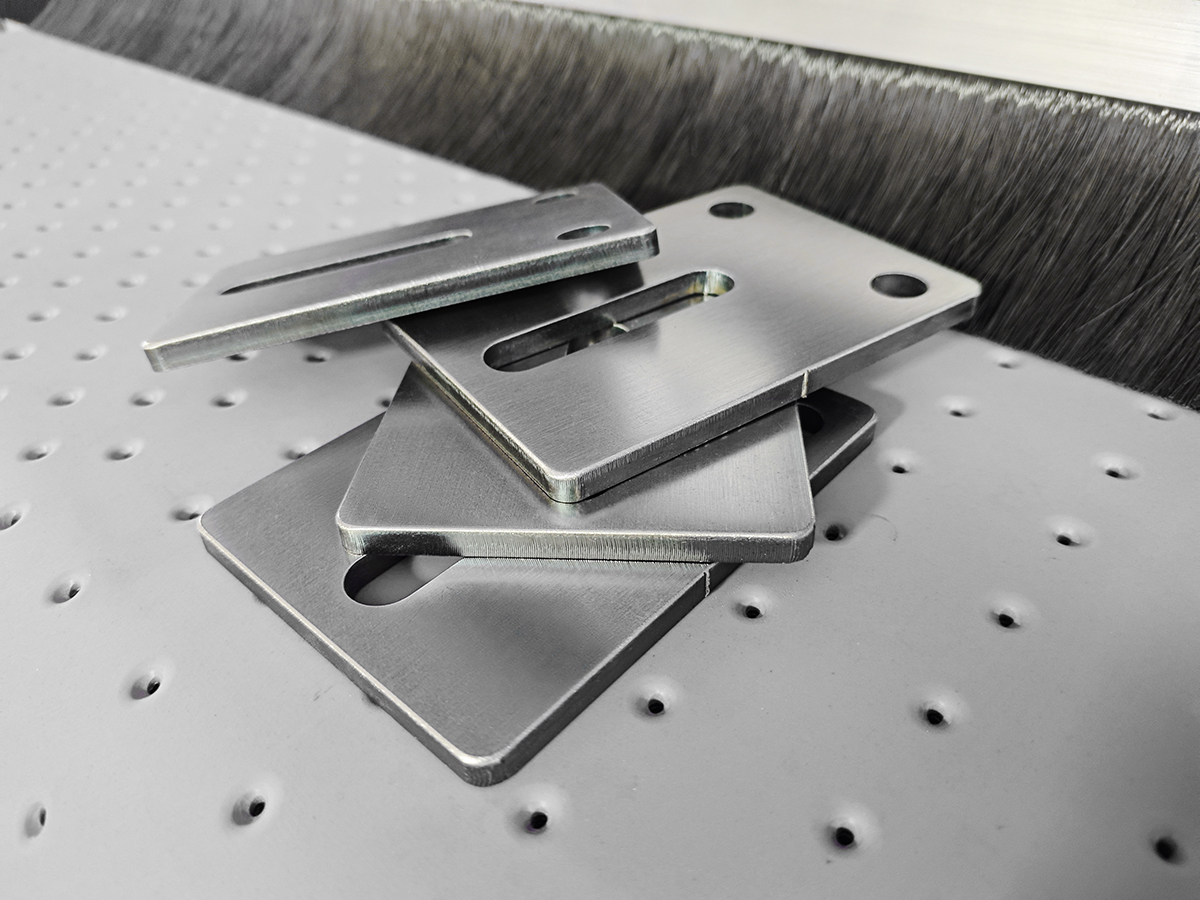

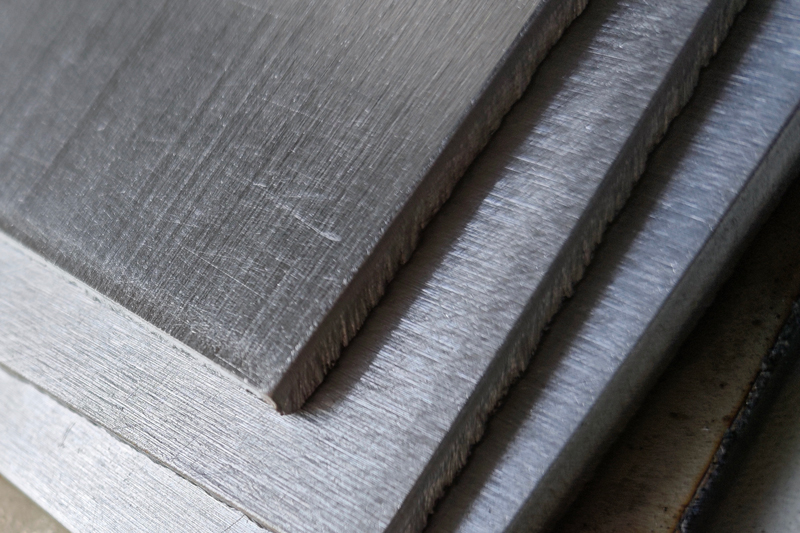

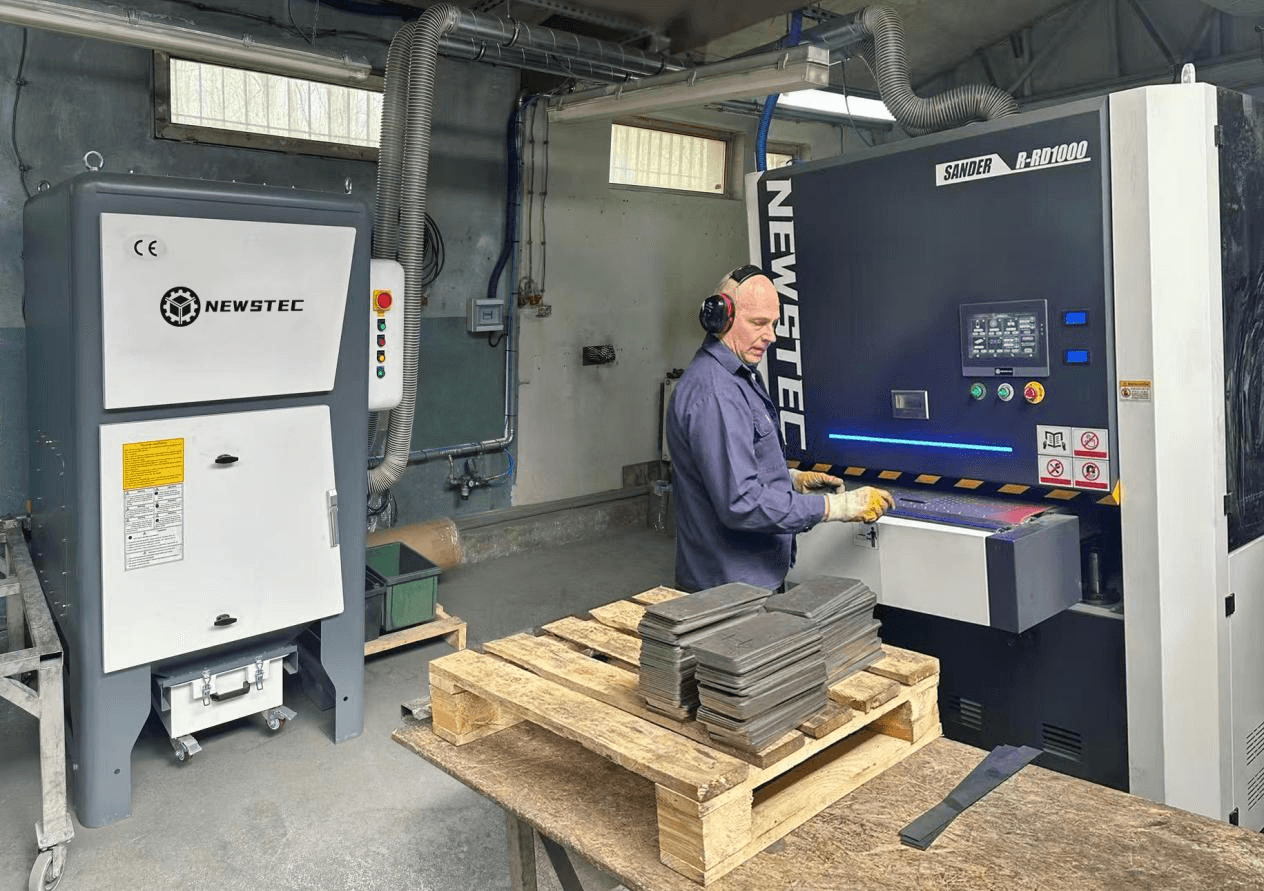

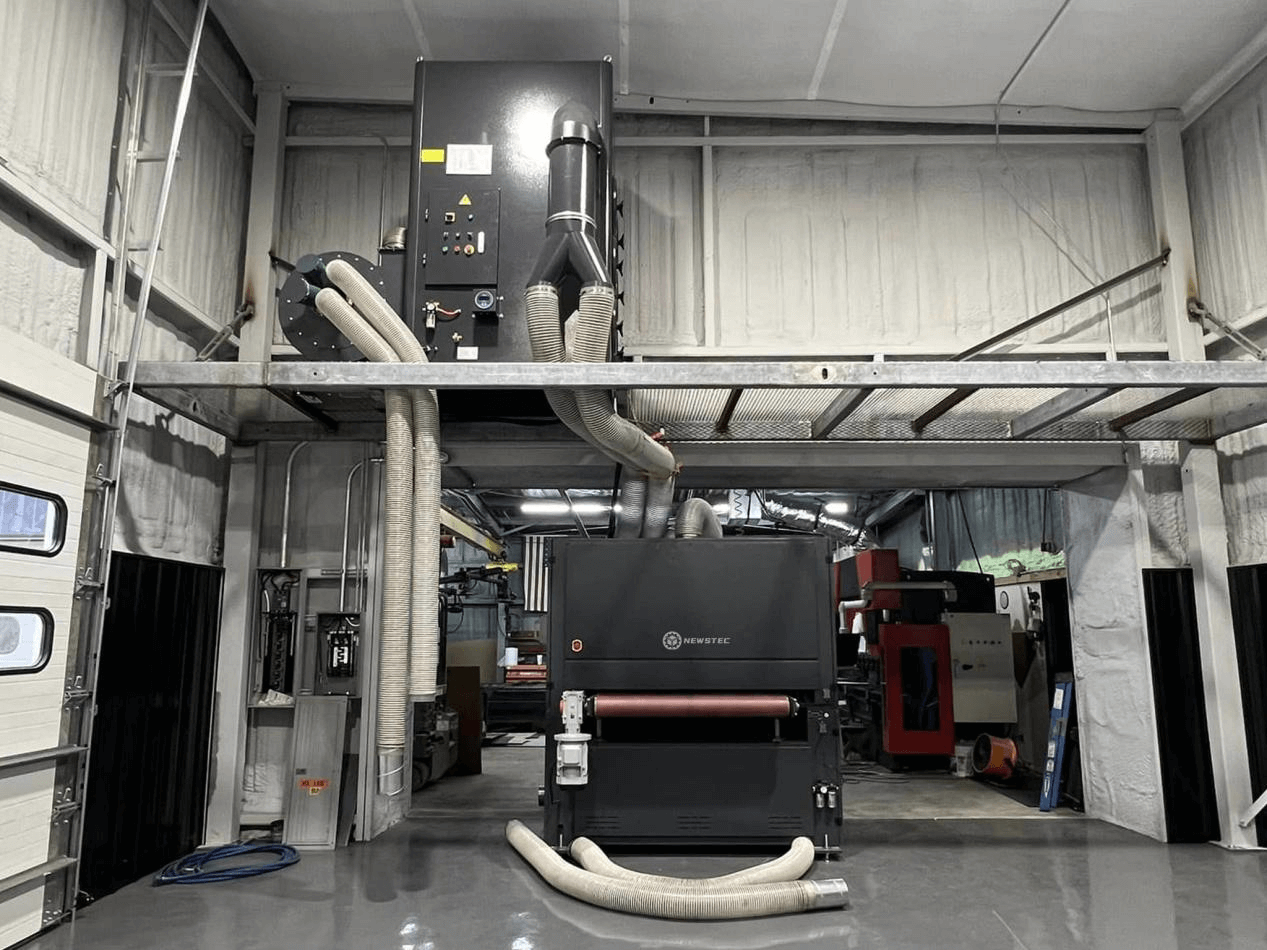

In the metalworking industry, metal deburring and Grinding Machines (used to remove burrs, flash, and optimize roughness on workpiece surfaces) generate large amounts of metal dust (such as iron, aluminum, and stainless steel debris). If not collected promptly, this not only pollutes the workshop environment and harms the health of operators, but can also cause equipment failures and safety hazards due to dust accumulation. Industrial dust collectors, as highly efficient dust collection devices, when used in conjunction with metal deburring and Grinding Machines, can control dust dispersion at the source and are a key solution for achieving clean production.

The operational characteristics of metal Deburring Grinders (high-speed grinding and flying metal chips) inevitably generate dust. Relying solely on simple protective measures (such as a small dust cover) on the grinder itself cannot meet industrial-grade cleaning requirements. Therefore, the necessity of an industrial dust collector is primarily reflected in three key aspects:

1. Protecting personnel health: Long-term inhalation of metal dust (especially fine dust, such as aluminum alloy dust) can cause occupational diseases such as pneumoconiosis and metal fume fever. Dust collectors can control dust concentrations within the safe range specified in the "Occupational Exposure Limits for Hazardous Factors in the Workplace" (GBZ 2.1) (e.g., iron dust ≤ 4 mg/m³).

2. Protecting equipment and workpieces: Floating metal dust can easily adhere to key components of the grinder, such as the motor, guide rails, and bearings, accelerating equipment wear. Furthermore, if dust adheres to the surface of the workpiece being machined or processed, it can affect grinding accuracy and workpiece quality (such as surface scratches and precision deviations). Dust collectors can reduce secondary contamination of equipment and workpieces by dust.

3. Avoiding Safety and Environmental Risks: Some metal dusts (such as aluminum and magnesium) are combustible and can easily explode when exposed to open flames or static electricity. Furthermore, uncollected dust emissions violate the "Comprehensive Emission Standard for Air Pollutants" (GB 16297). Pairing a dust collector can address both safety and environmental compliance issues.

The combination of a metal Deburring Grinder and an industrial dust collector controls dust generation and dispersion at the source, safeguarding worker health, equipment stability, and workpiece quality while meeting environmental and safety compliance requirements. It is a key component for achieving clean production in modern metalworking workshops.