How to Choose the Right Worktable for a Metal Sheet Deburring Machine

In Metal Deburring Machines, vacuum tables and strong magnetic tables are two core fixing solutions designed specifically for the characteristics of metal workpieces. Both are optimized for metal processing, with significant differences in terms of application scenarios, deburring suitability, and operational details.

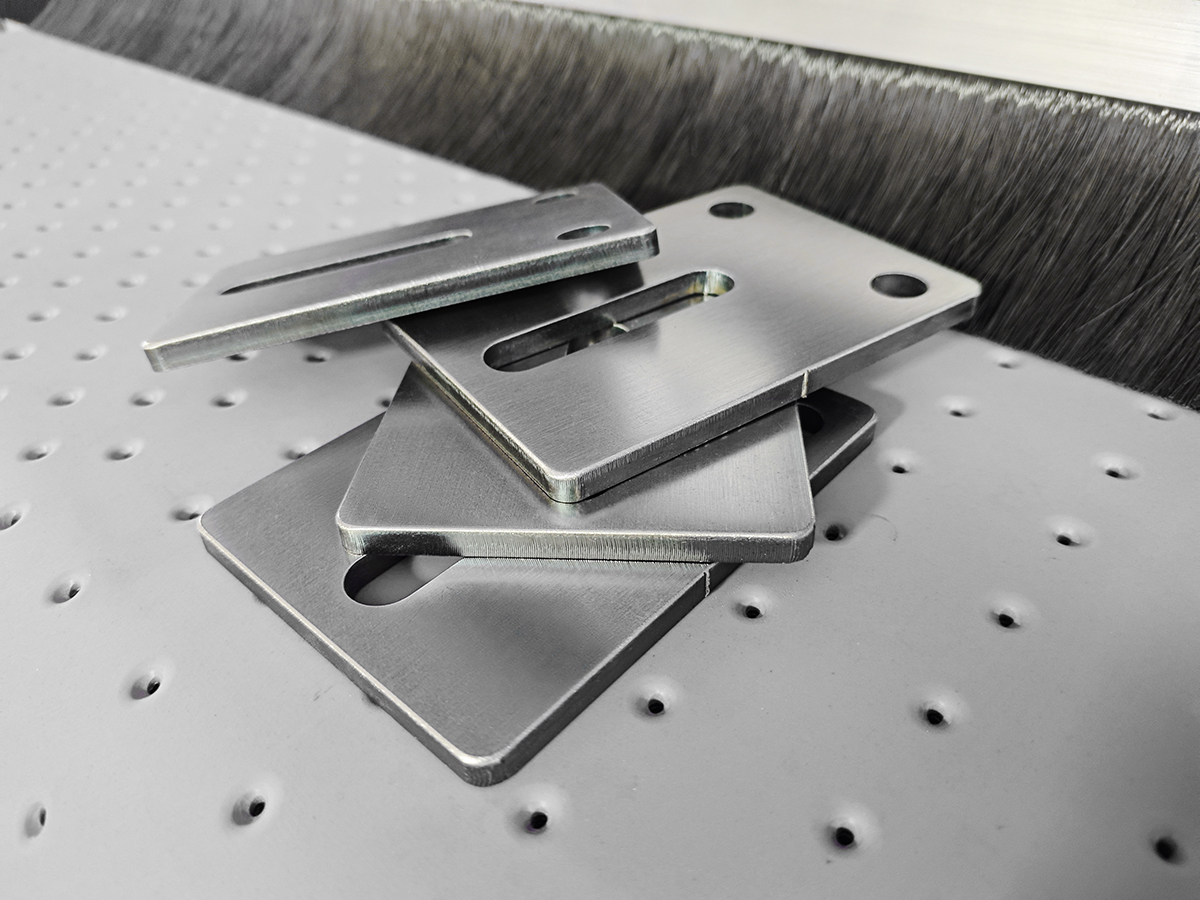

A vacuum table uses a vacuum pump to generate negative pressure, creating a pressure differential between a specific area of the table and the material surface. This creates a suction force that securely holds the material to the table. Suitable for non-magnetic metal processing, such as deburring aluminum alloys, copper parts, and stainless steel.

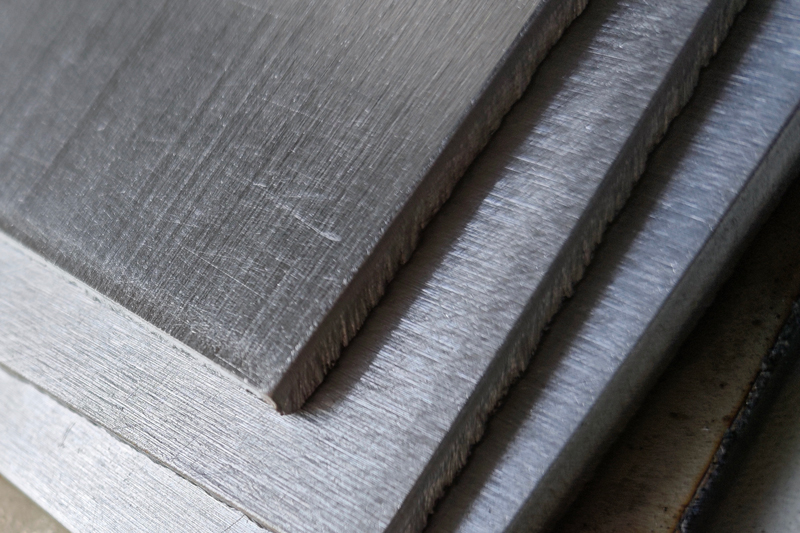

A strong magnetic table utilizes a magnetic field generated by a permanent magnet or electromagnetic coil to create a strong attraction to magnetic materials, securing the workpiece to the table. Suitable for high-performance processing of magnetic metals, such as deburring carbon steel gears, deburring cast iron (grinding with a grinding wheel), and deburring thick steel plate edges.

Selecting a Metal Deburring Machine tabletop essentially depends on matching material compatibility with processing requirements: vacuum for non-magnetic, fine processing, and strong magnetic for magnetic, high-performance processing. If processing multiple materials (such as aluminum and steel simultaneously) is required, a "vacuum + strong magnetic" composite tabletop can be considered.