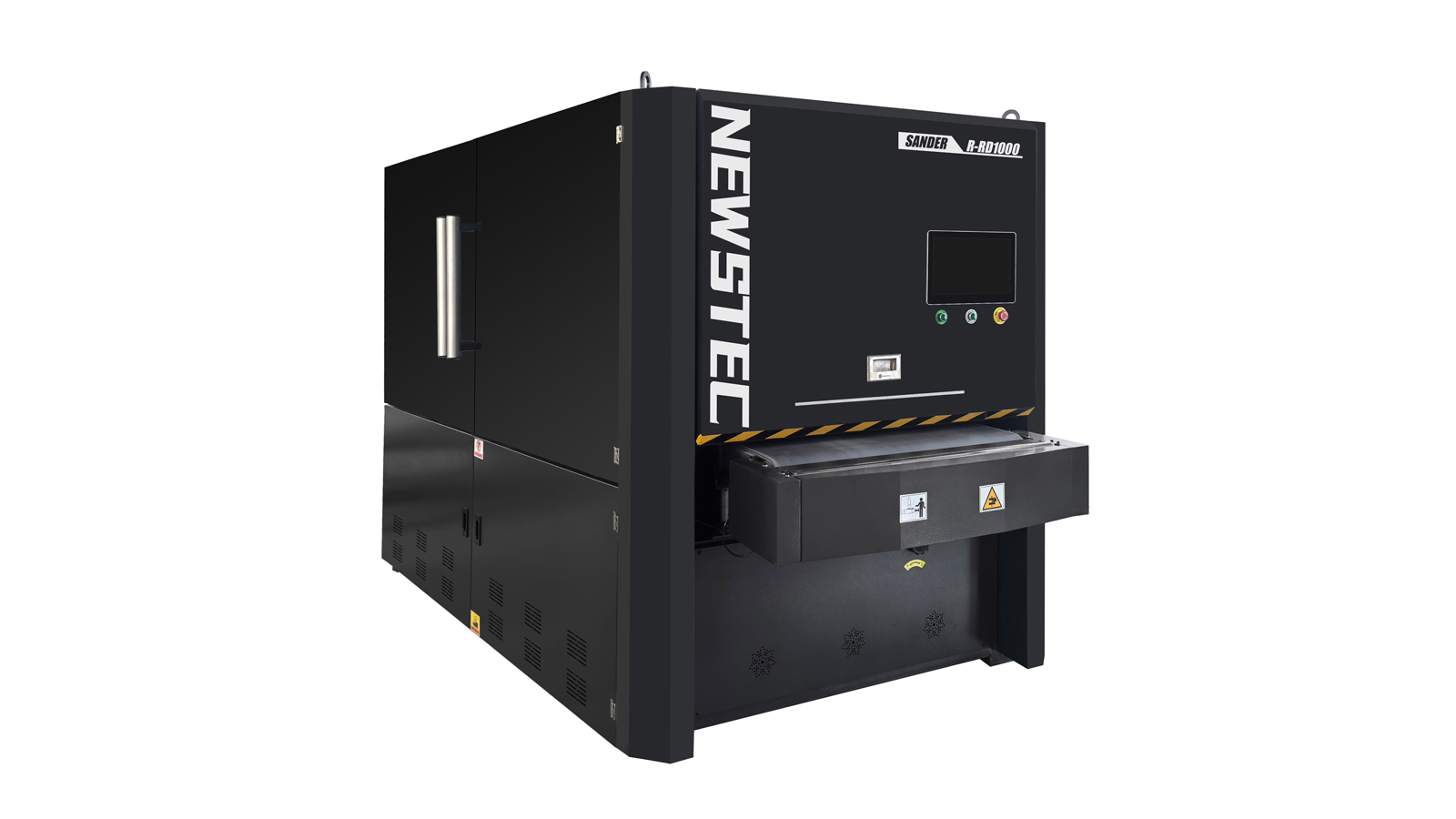

1000mm Metal Deslagging Deburring chamfering Machine

0102030405

Parameters

| Working width(mm) | 1300 |

| Min.Working length(mm) | 300 |

| Working thickness(mm) | 0-100 |

| Abrasive belt motor(kw) | 18.5 |

| Rotary brush motor power(kw) | 2.2X3 |

| Total Power | 44kw |

| Transmission motor power(kw) | 4 |

| Lift motor power | 0.55 |

| No.1 unit of belt shelf | 210mm |

| Adsorption | 11kw 2900RPM |

| Controller system | Delta PLC |

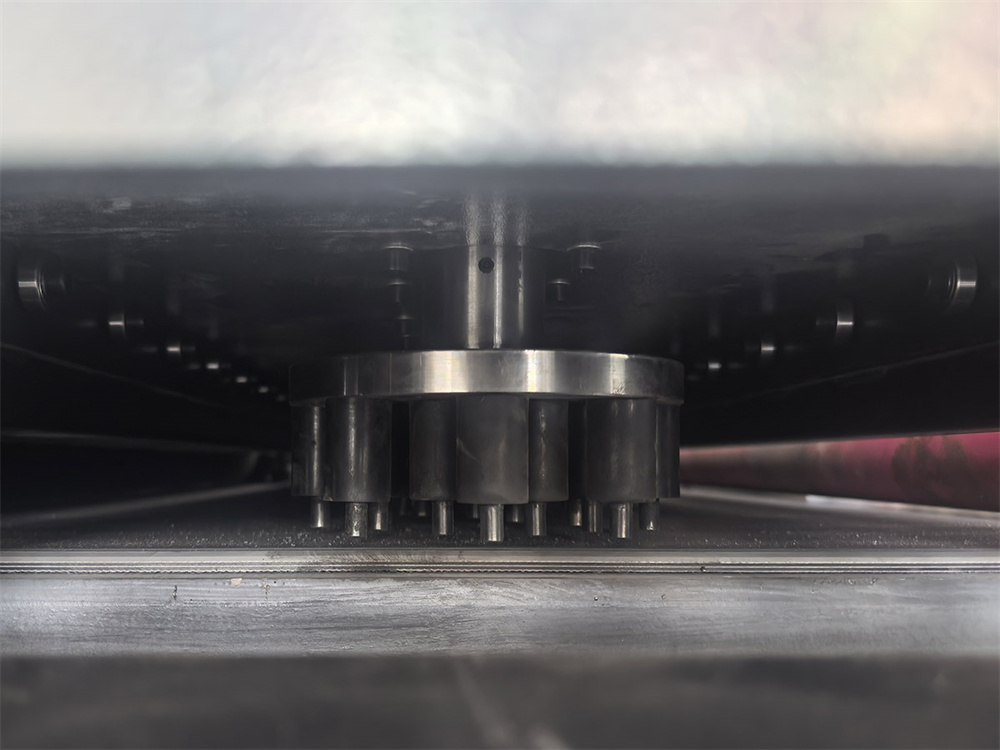

| Rotary brush size(mm) | 300x300x25 |

| Rotary brush quantity | 6 |

| Voltage | 220v/380V3PH |

| Power | 50/60HZ |

| Abrasive belt size(mm) | 1320*2020mm |

| Overall dimensions(mm) | Machine :2700*2300*2100mm Vacuum pump :1000*1000*2000mm |

| Gross Weight(with wooden case)(kg) | 3200KGS |

product description

This equipment has significant advantages in slag removal and surface grinding of thick metal plates.

During the thick plate cutting process, high temperature will form a large amount of hard slag.

Manual cleaning is not only inefficient, but also easy to damage the parent material.

The metal slag remover can quickly remove the stubborn slag on the surface of the thick plate through customized grinding tools and grinding systems, and complete the preliminary surface finishing at the same time.

It can effectively handle the residues generated by various cutting processes, including slag formed after plasma cutting, flame cutting and laser cutting. In addition, for defects such as burrs and flash on the edge and surface of metal plates, the equipment can achieve all-round cleaning through multi-axis linkage technology to ensure that the edge of the plate is smooth and flawless.

In terms of surface treatment, the metal slag remover has the function of removing the surface oxide layer.

Metal materials are prone to form oxide scale during processing or storage, which affects the quality of subsequent welding, painting and other processes.

The equipment can completely remove the oxide layer through precision grinding to reveal the original luster of the metal substrate.

With high-precision control systems and diversified processing modes, metal slag removers can achieve high-quality metal surface treatment effects, which not only improves the appearance quality of metal parts, but also enhances the durability and safety of products.

It plays an irreplaceable role in engineering machinery, shipbuilding, pressure vessels and other industries.

-

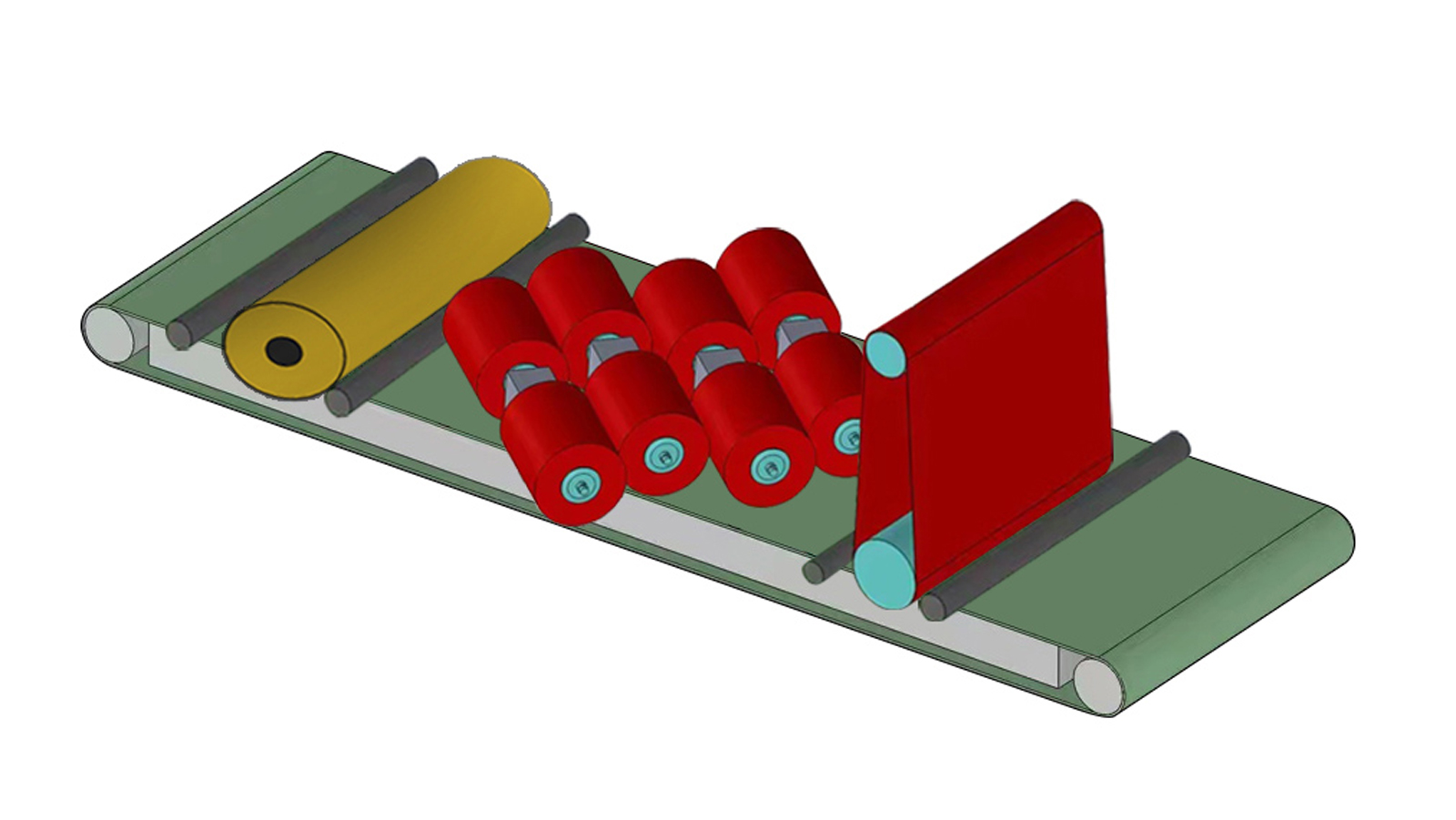

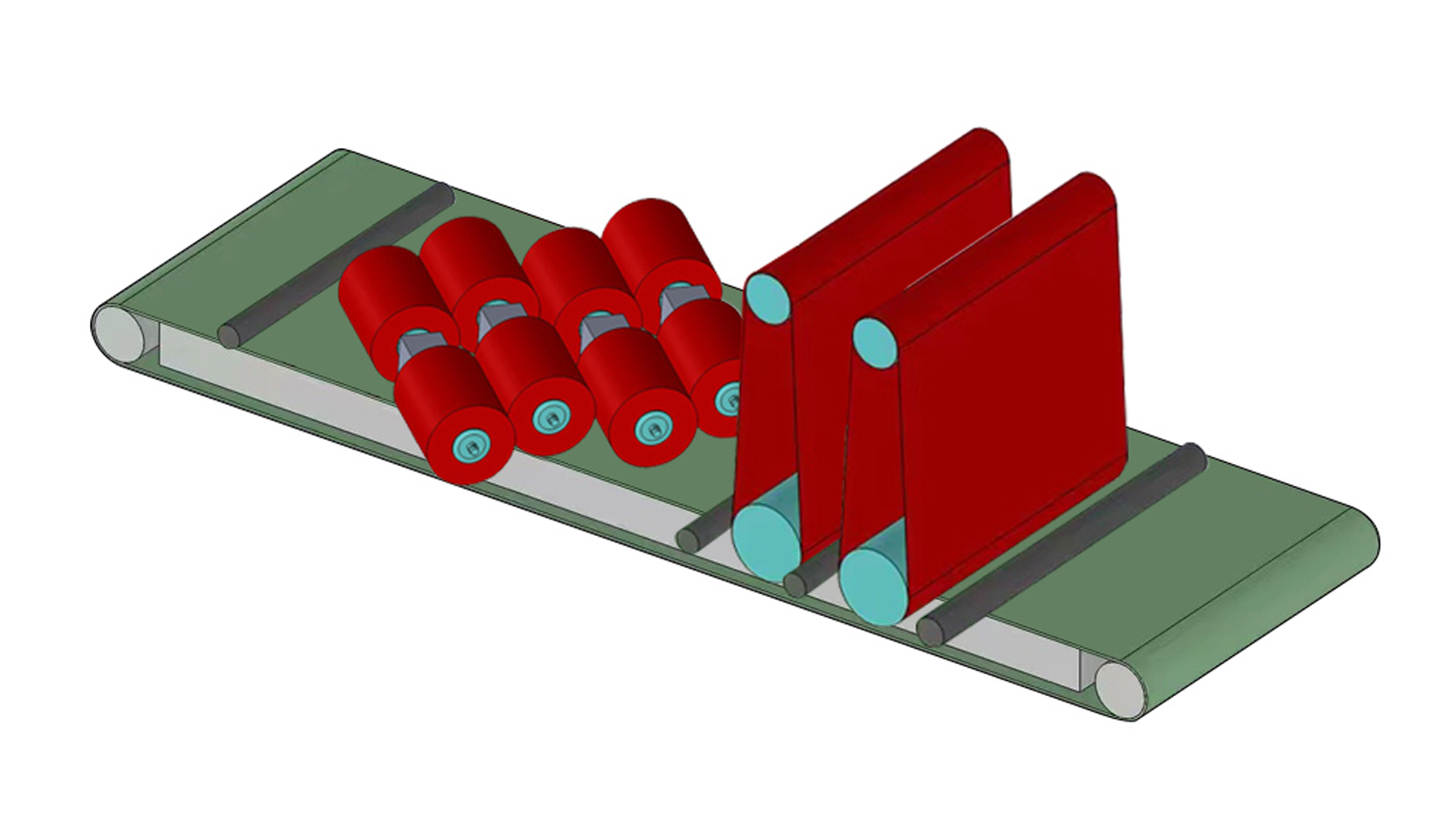

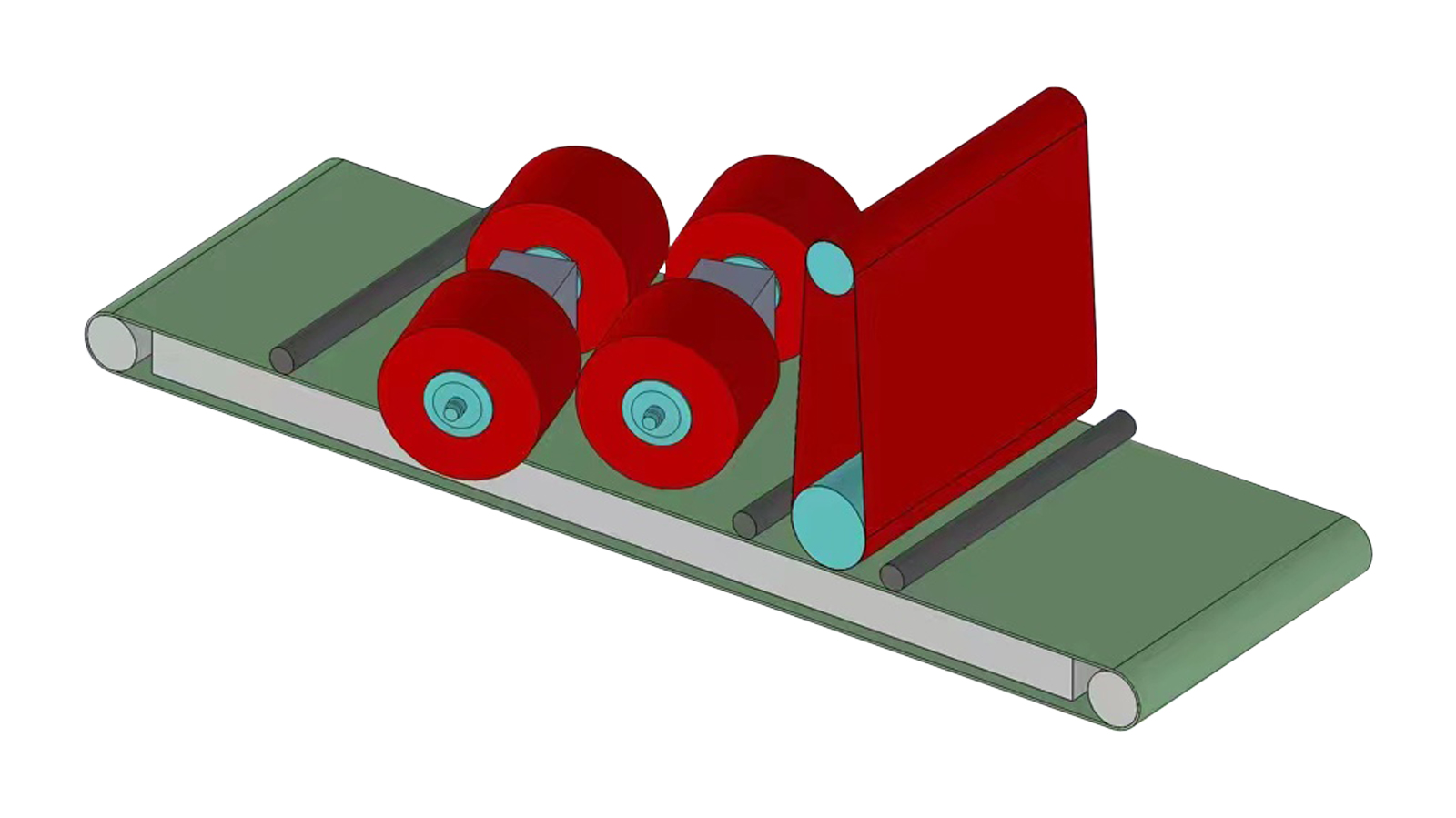

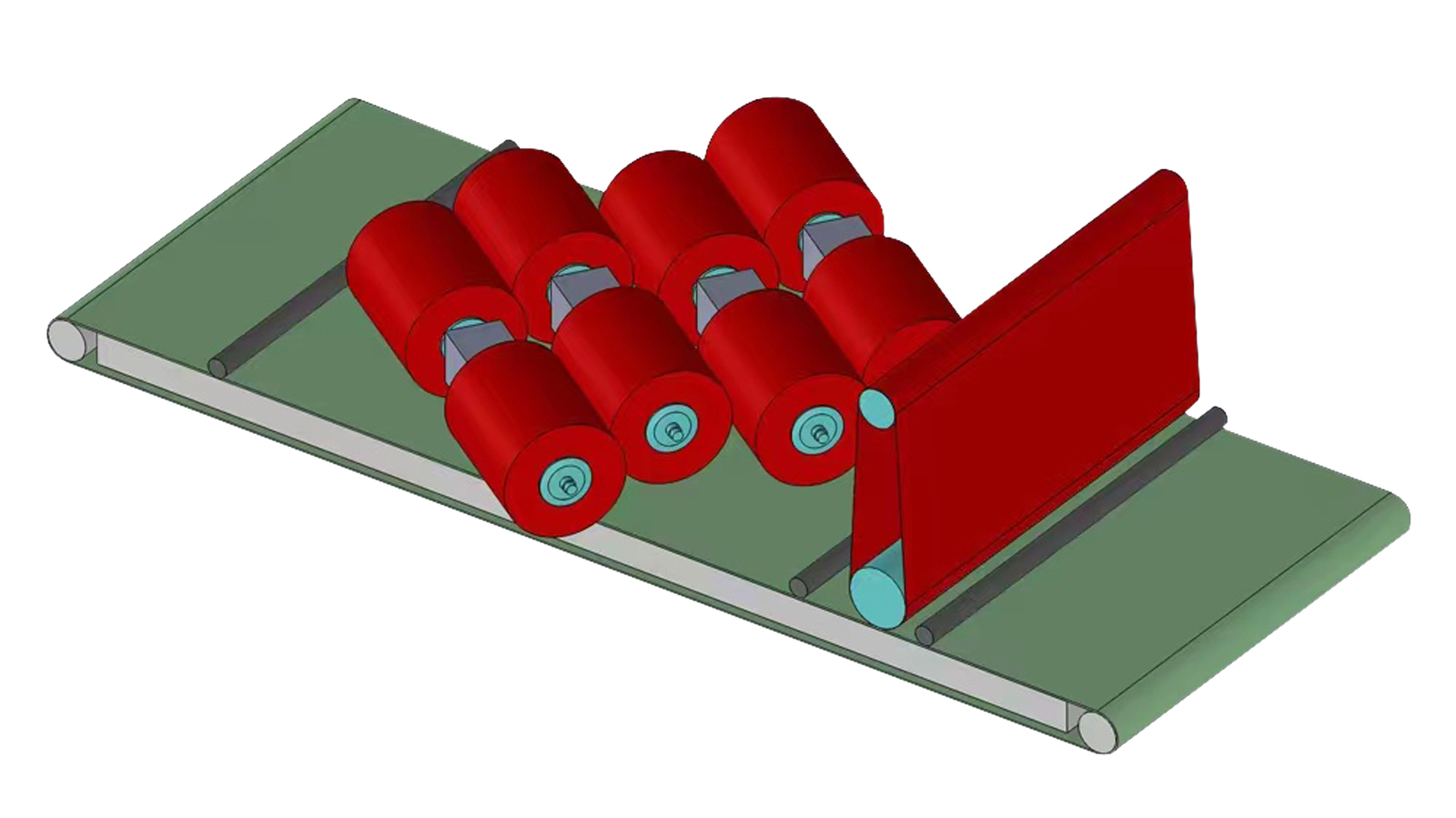

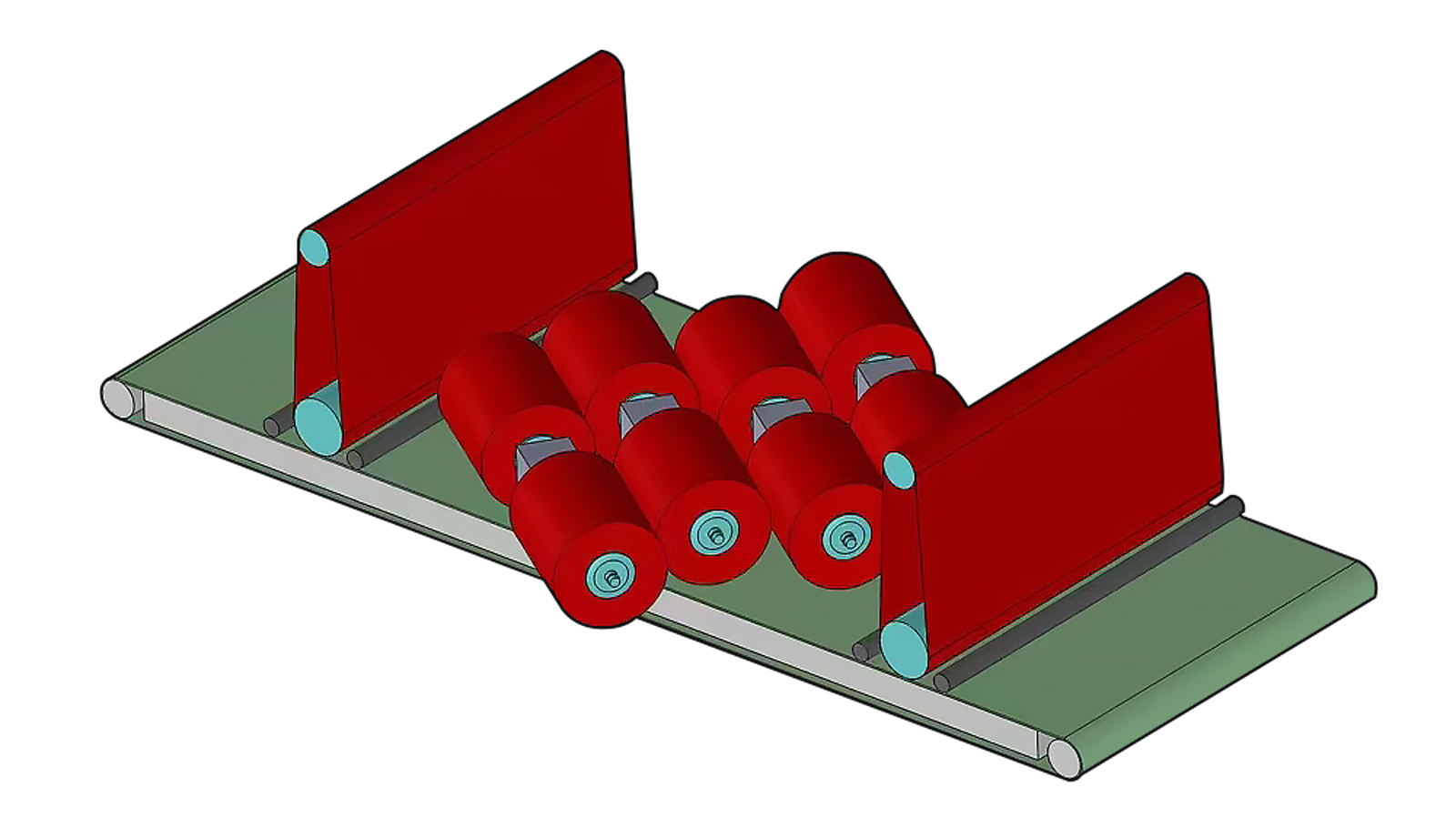

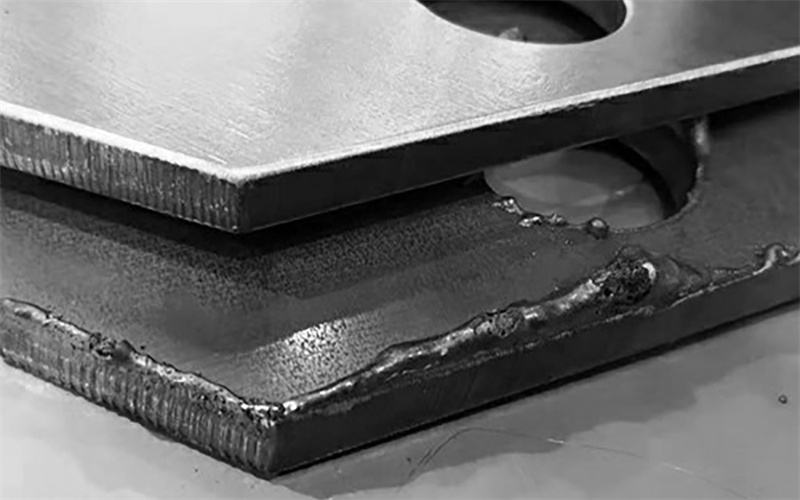

HAMMER DISC

Developed for removing slag from both sides of thick plate parts. It is ideal for flame cutting, plasma cutting and laser cutting of slag parts. Use the slag hammer to remove slag, saving time and manpower.

-

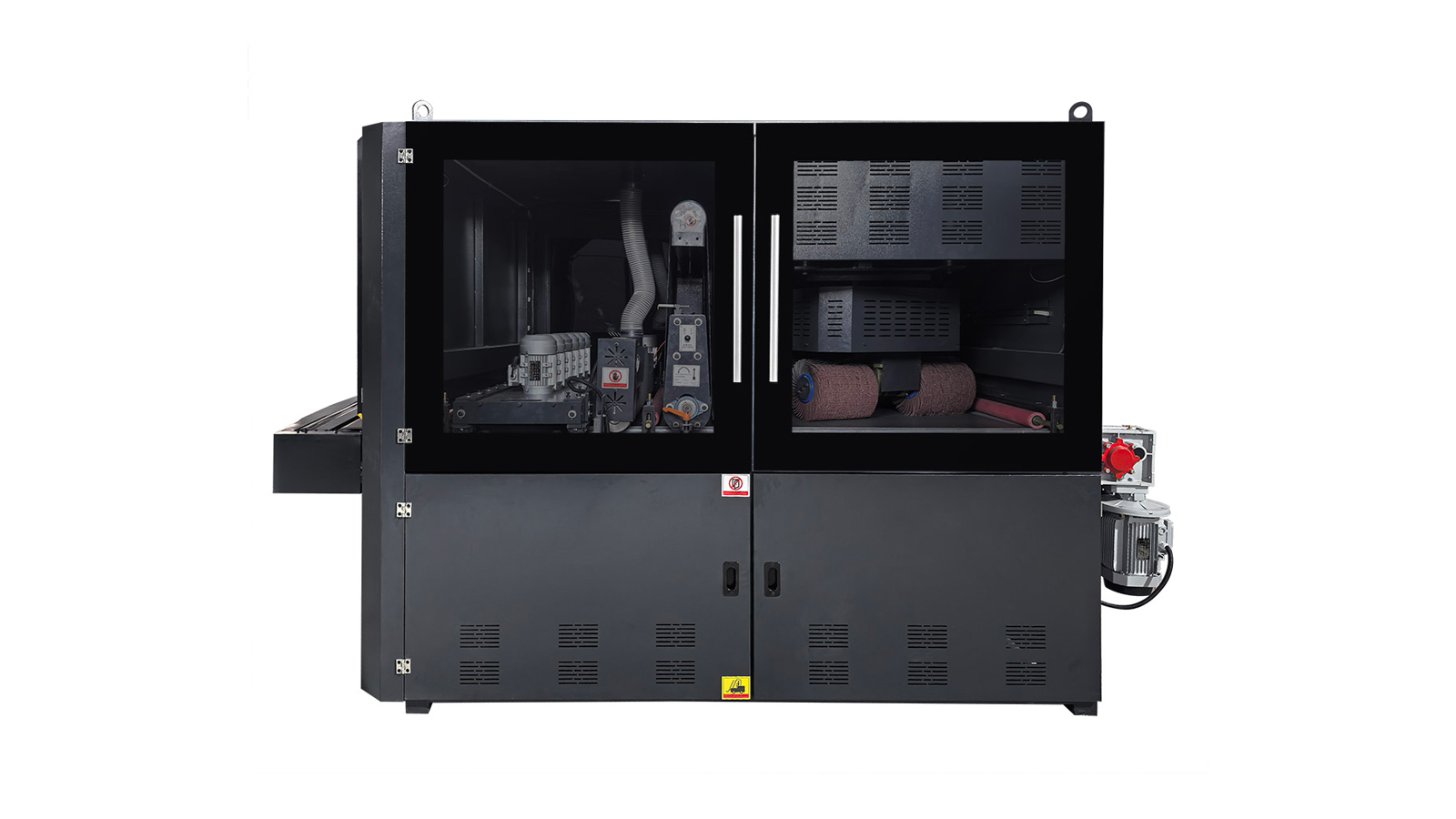

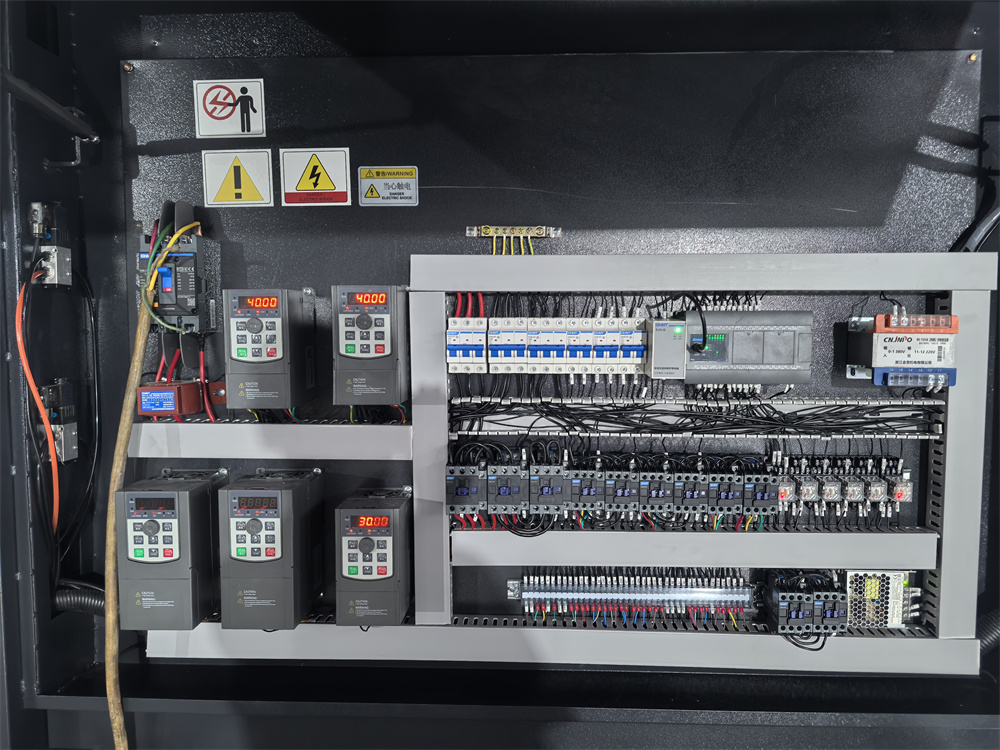

INTERNAL CIRCUITAIl

The electrical parts are made of Chint electric appliances with stable performance. The machine internal wire connection is clear, no clutter.

-

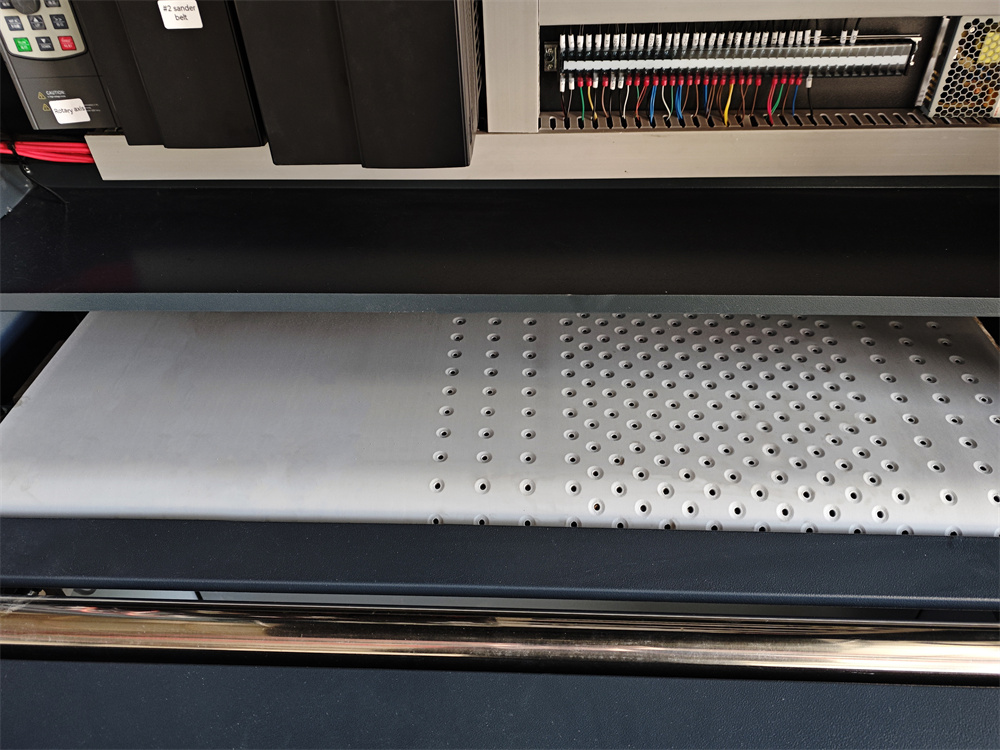

VACUUM AND MAGNETIC WORKBENCH

Safe adsorption, uniform suction, stable workpiece, improve processing accuracy, improve grinding efficiency, complete the surface processing of metal sheet.

-

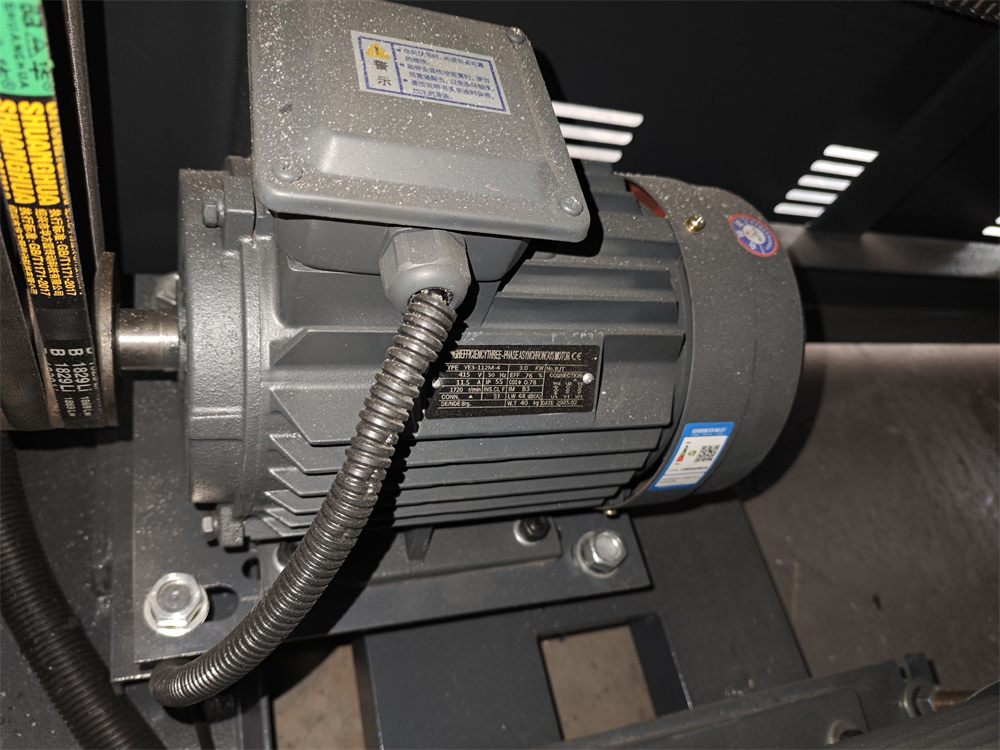

MOTORS

Sanding machine adopts copper coremotor, stable and durable long servicelife