800mm Industrial Wet Wide Belt Metal Sanding Deburring Machine

010203

Parameters

| Working width(mm) | 630 |

| Min.Working length(mm) | 300 |

| Working thickness(mm) | 0-110 |

| First motor(kw) | 11 |

| Second motor(kw) | 7.5 |

| Total Power | 19.97 |

| Transmission motor power(kw) | 1.1 |

| Abrasive belt size(mm) | 650*1900 |

| Overall dimensions(mm) | 1800*1200*2100 |

| Weight(kg) | 1300 |

product description

During the wet processing process, the grinding fluid can continuously take away the heat generated during the sanding process, so that the workpiece is always in a cold processing state. This effectively avoids the problem of workpiece deformation caused by high temperature, which is particularly important for some metal sheet processing with high dimensional accuracy requirements. For example, in the processing of metal shells of precision electronic equipment, the use of wet sanders can ensure the dimensional accuracy and surface flatness of the shell and improve product quality.

The wet processing method can absorb all the dust generated during the grinding process into the grinding fluid, avoiding the flying of dust in the air. This not only improves the working environment, protects the health of operators, reduces the risk of occupational diseases, but also reduces the damage of dust to equipment and extends the service life of equipment. In some production workshops with strict control of dust pollution, wet metal sheet sanding machines have become the preferred processing equipment.

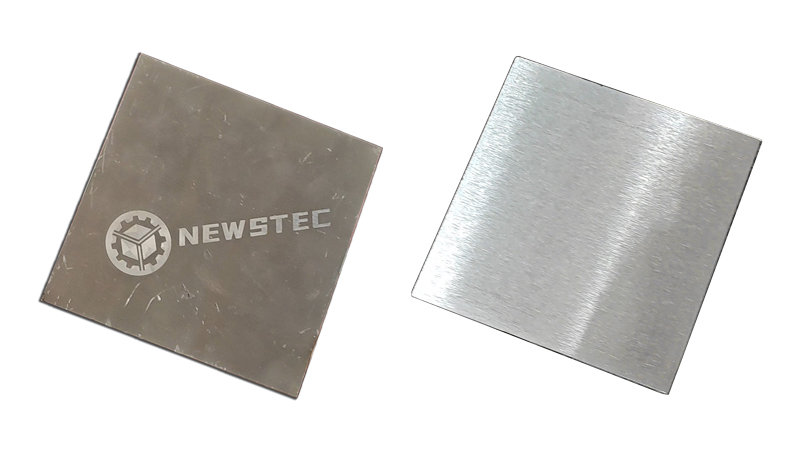

Rust removal, deburring, oxidation removal, wire drawing grinding and polishing of the metal plate.

-

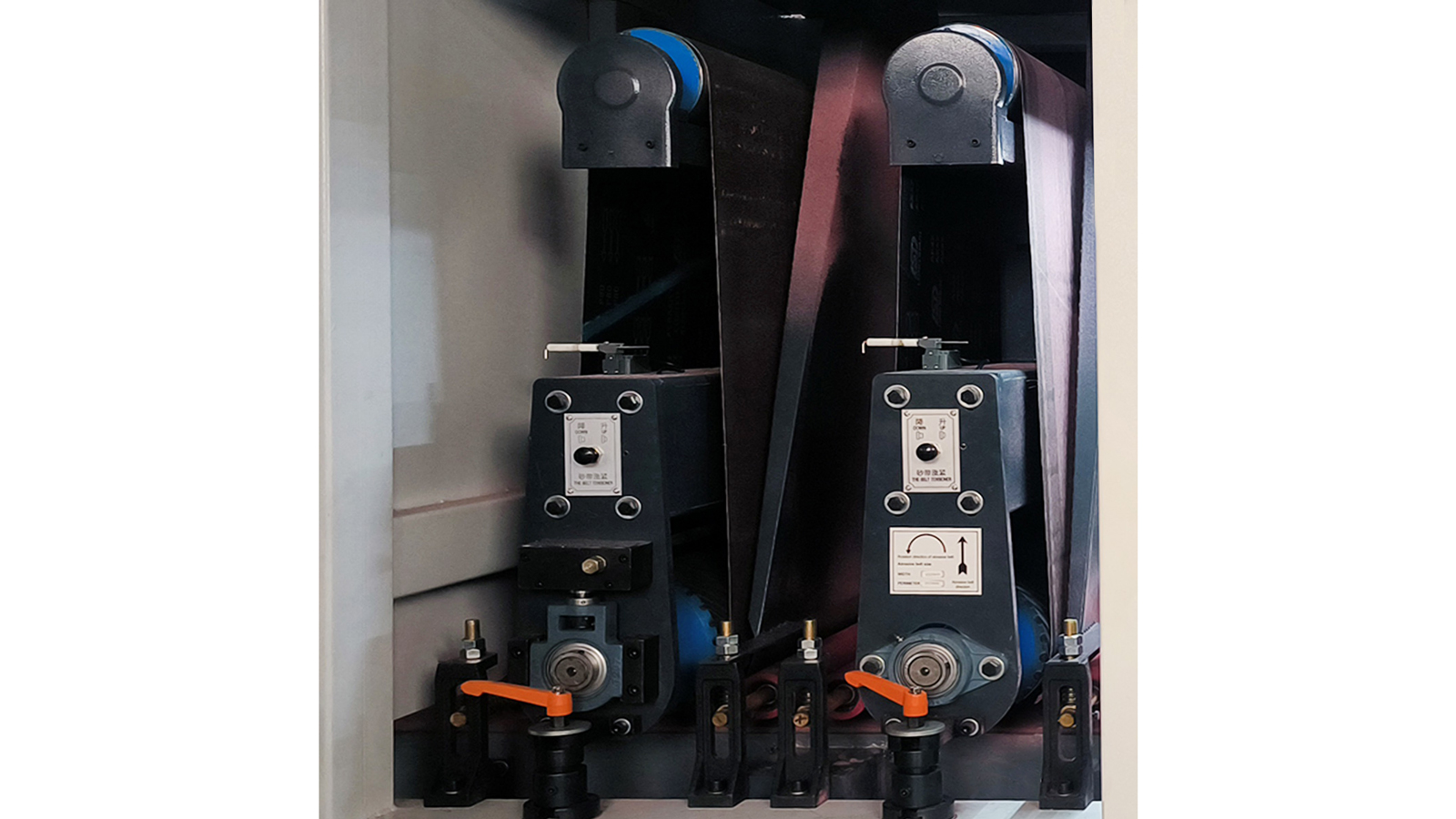

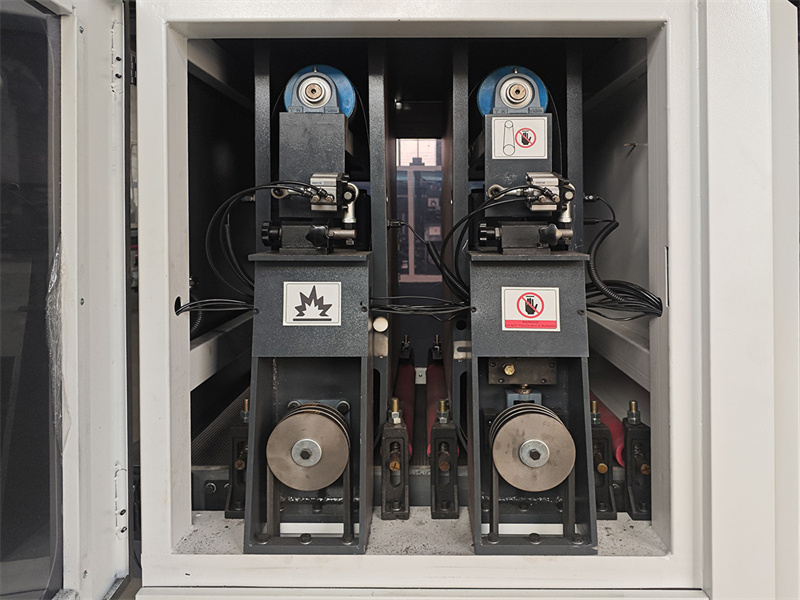

SANDING BELT

By grinding the stainless steel, carbon steel, molybdenum plate, etc., cleaning the plate due to laser cuting, stamping burs,grinding to remove the oxide layer, deburing, so as to show the metal bright surface, processing plate width 600mm, 1000mm, 1300mm, 1600mm, etc.

-

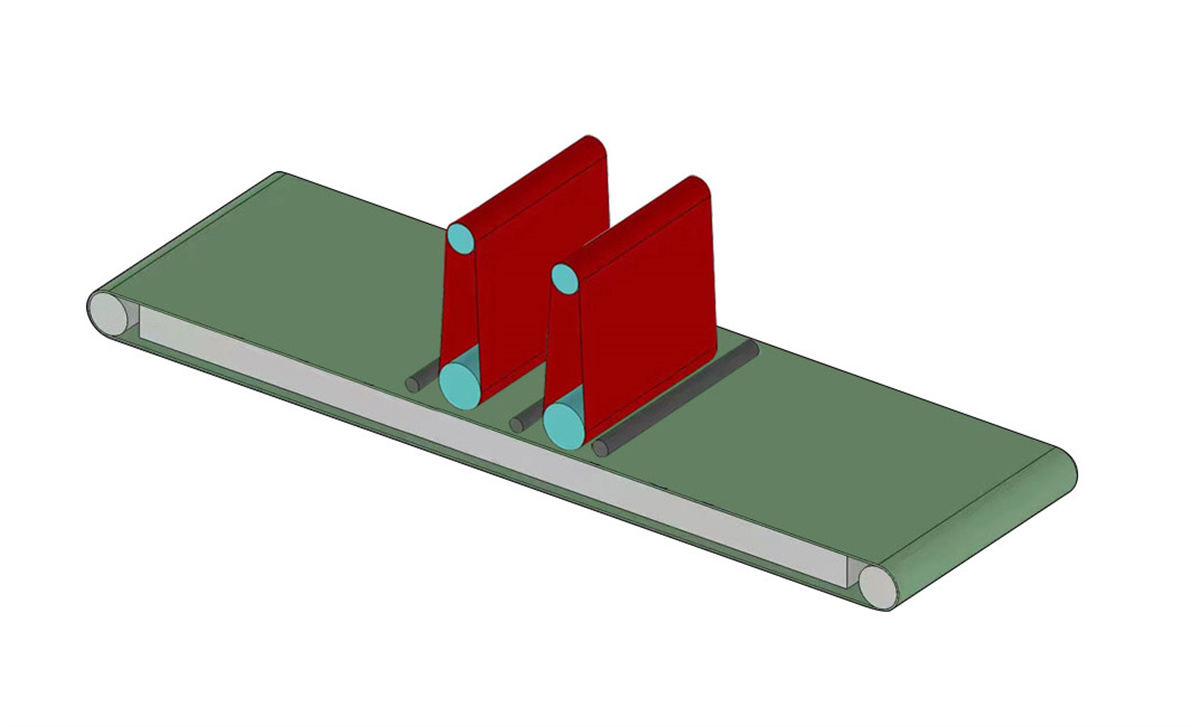

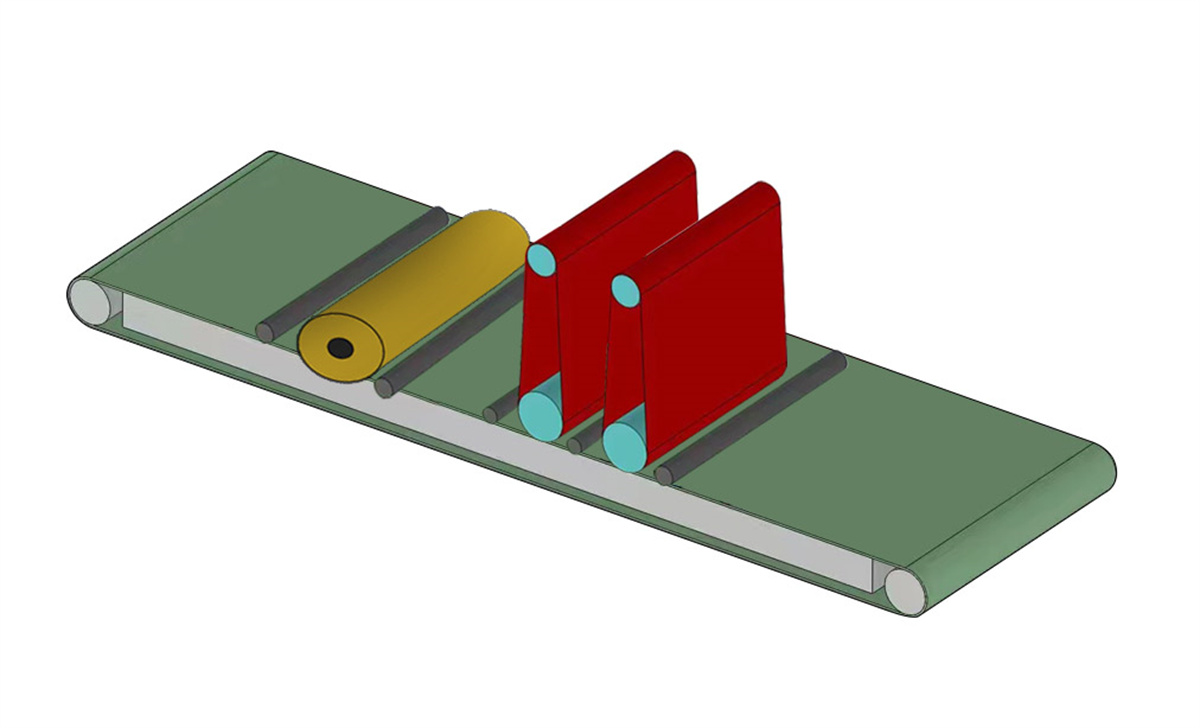

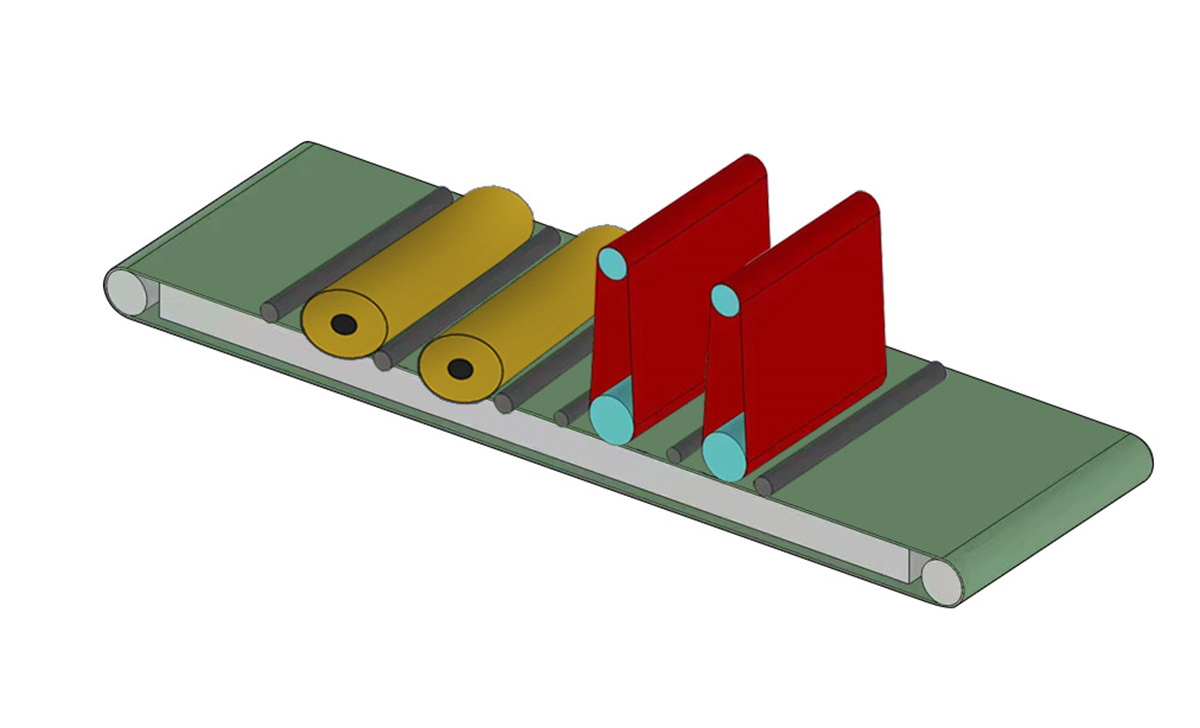

CONVEYOR BELT

Working table for the thickened marble, conveyor belt for five layers of rubber material, not afraid of rain, not afraid of sun, long service life.

-

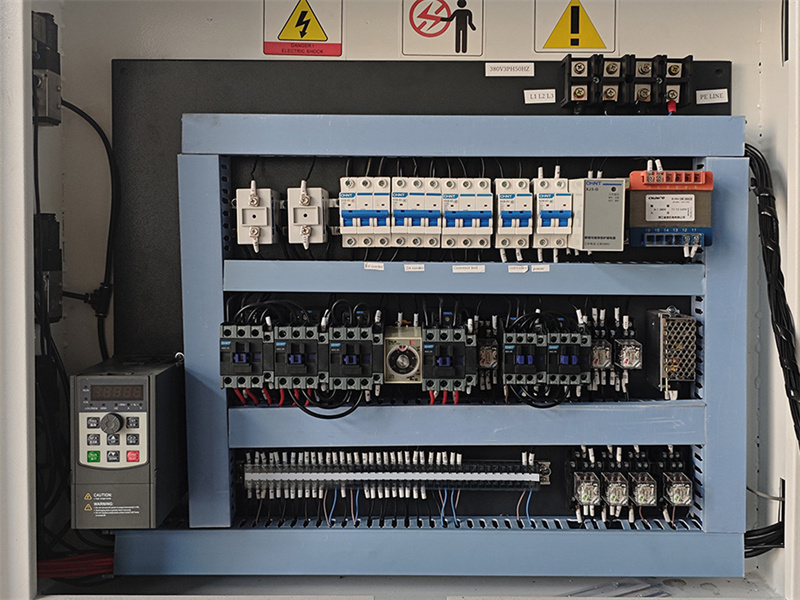

INTERNAL CIRCUIT

All the electrical parts are made of Chint electric appliances with stable performance. The machine internal wire connection is clear, no clutter.

-

CONTROL PANEL

The control panel is simple and clear, the self-reset control button has high control precision and easy operation.