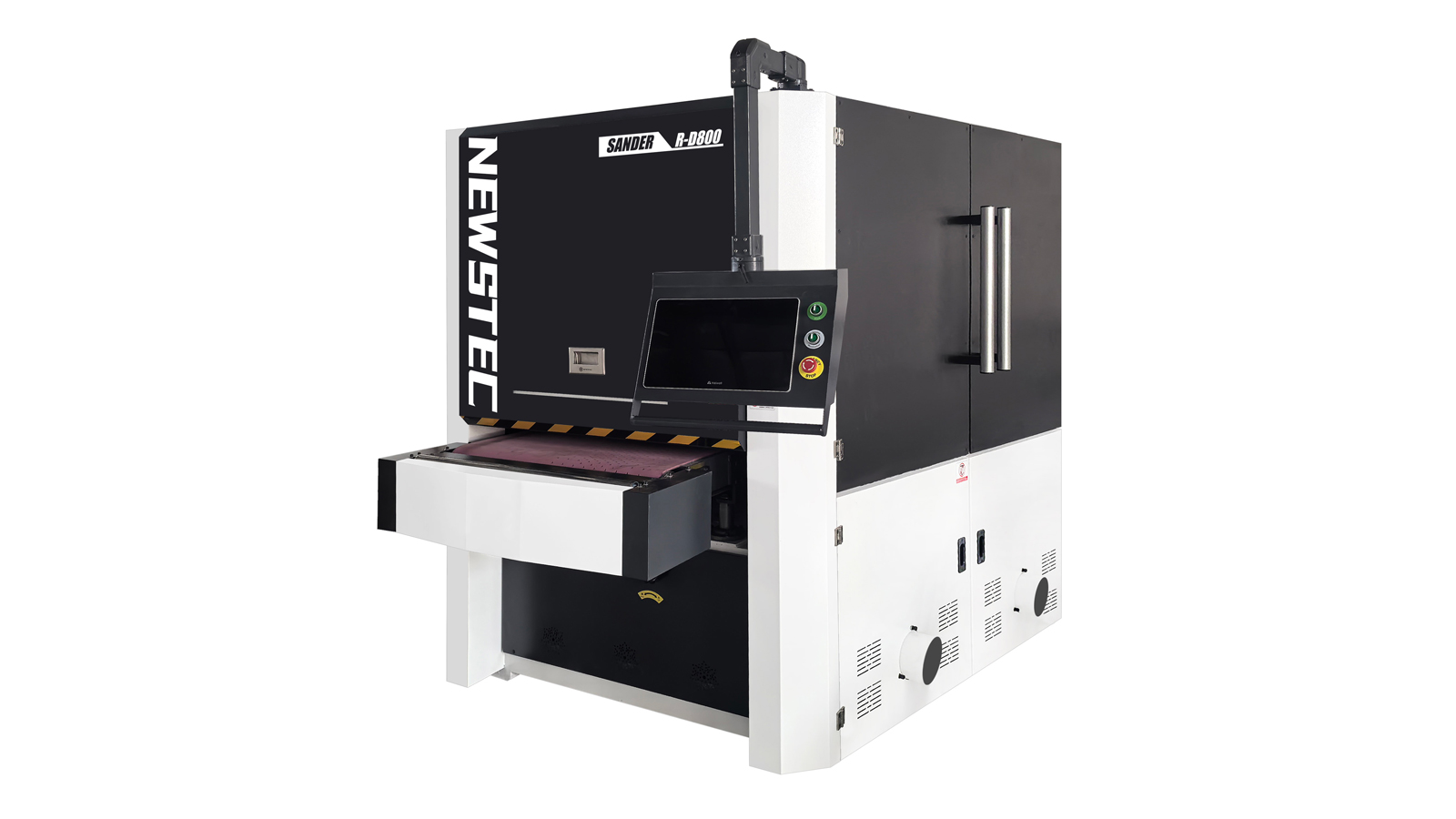

800 mm Industrial Metal Sheet Deburring And Chamfering Machine

010203

Parameters

| Working width(mm) | 800 |

| Min.Working length(mm) | 300 |

| Working thickness(mm) | 0-100 |

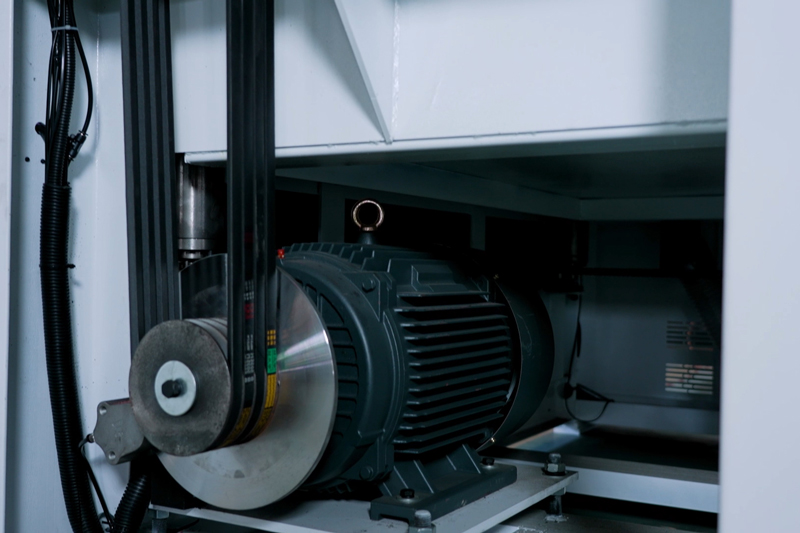

| Abrasive belt motor(kw) | 18.5 |

| Rotary brush motor power(kw) | 2.2X3 |

| Total Power | 44kw |

| Transmission motor power(kw) | 4 |

| Lift motor power | 0.55 |

| No.1 unit of belt shelf | 210mm |

| Adsorption | 11kw 2900RPM |

| Controller system | Delta PLC |

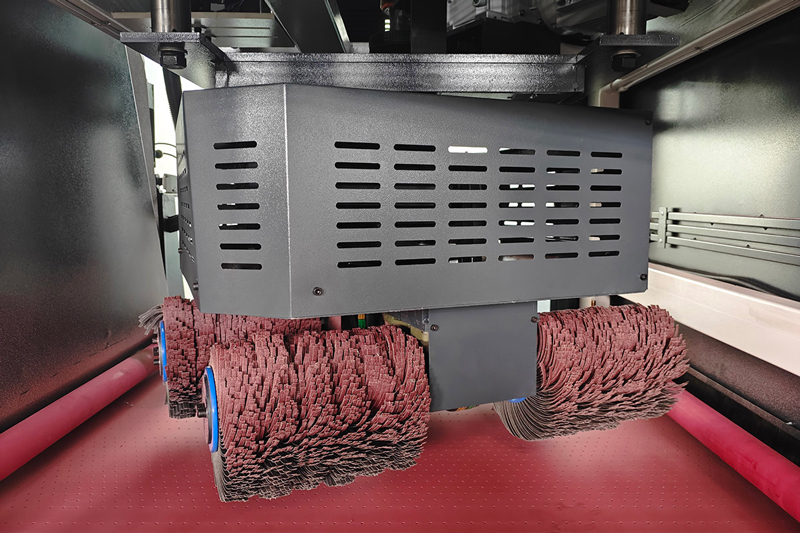

| Rotary brush size(mm) | 300x300x25 |

| Rotary brush quantity | 6 |

| Voltage | 220v/380V3PH |

| Power | 50/60HZ |

| Abrasive belt size(mm) | 800*2000mm |

| Overall dimensions(mm) | Machine :2700*1500*2000mm Vacuum pump :1000*1000*2000mm |

| Gross Weight(with wooden case)(kg) | 3200KGS |

product description

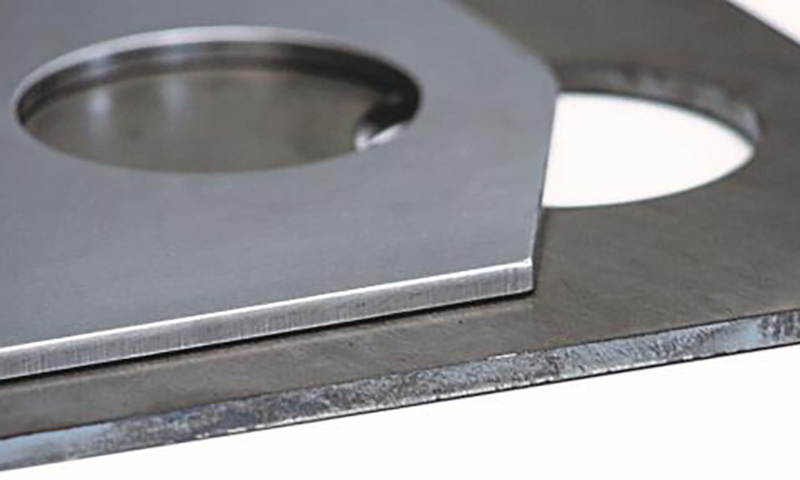

The equipment integrates multiple core functions and can complete pre-grinding, wire drawing, polishing, scratch removal, deburring and chamfering passivation processes to achieve one-stop surface and edge processing. For workpieces processed by laser cutting, shearing, stamping, water jet cutting, etc., it can accurately deal with burrs and slag generated on the edges.

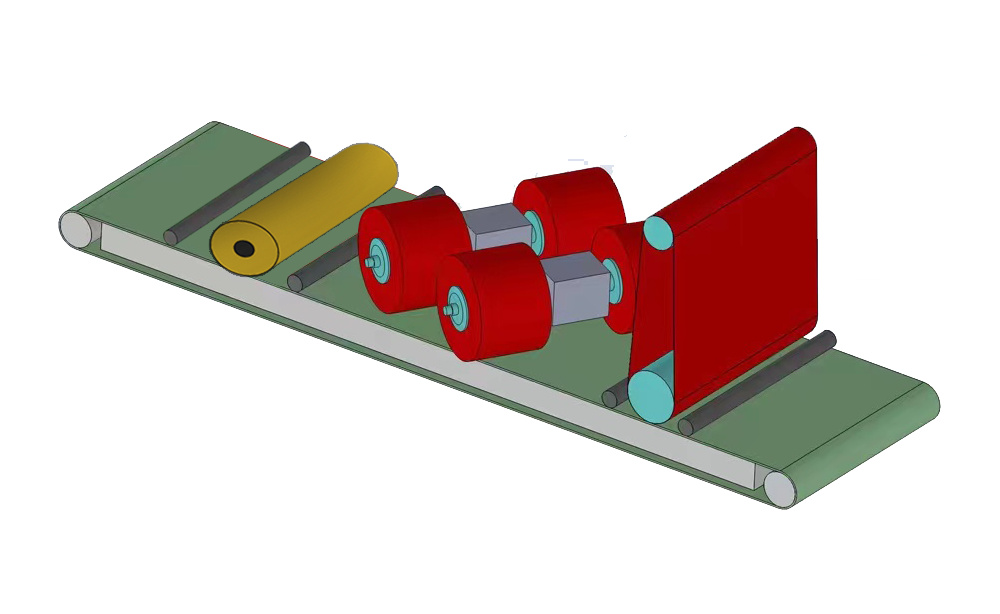

Its working principle adopts a linear processing mode. Multiple sets of abrasive wheels rotate, revolve and alternately operate to ensure uniform removal of burrs on the surface of parts, contour edges and hole edges, and achieve precise chamfering.

The equipment can be matched with processing equipment such as laser cutting machines and CNC stamping to form a complete deburring edge production line.Whether it is a high-hardness carbon steel plate, a stainless steel plate that requires precision, or a softer aluminum plate or copper plate, the equipment can adjust parameters according to the material characteristics, effectively removing burrs while protecting material properties.

It effectively solves the pain points of sharp edges and many defects in metal processing, improves product safety and assembly accuracy, and is an indispensable processing auxiliary equipment in modern manufacturing.

-

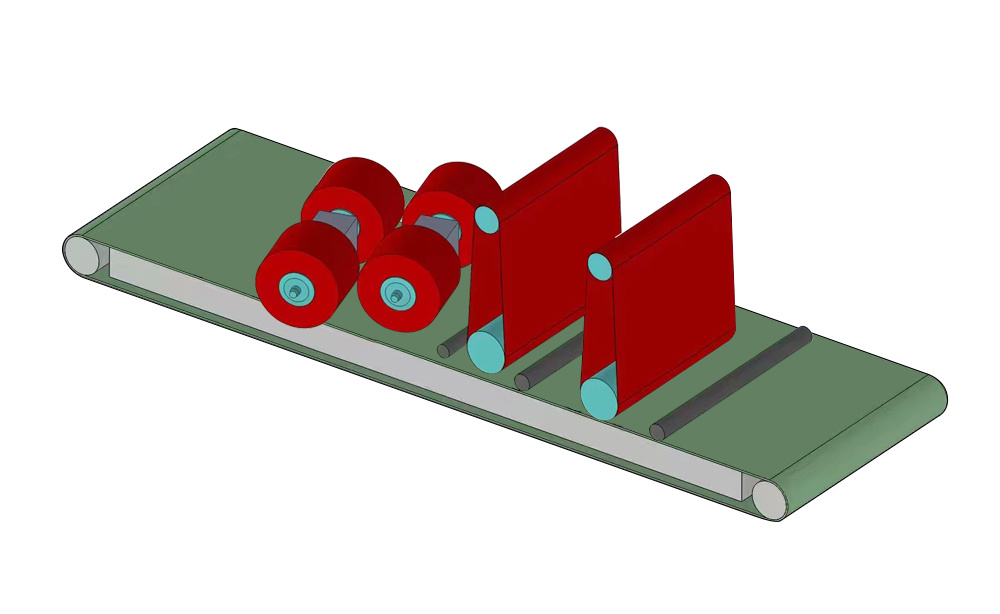

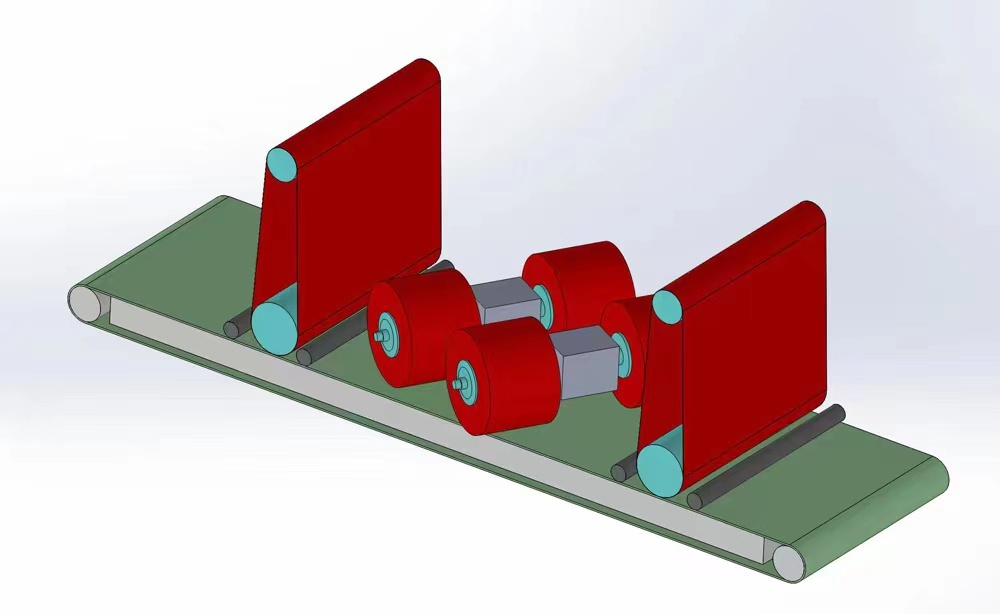

UNIT STRUCTURE

Each unit is independently controlled and can be combined as needed.

-

ROTARY

Deburring, chamfering and finishing of internal and external contours.

-

MOTOR

Copper core motor, stable and durable, long service Ife.

-

PLATFORM LIFTING

0-100mm lifting platform precise lifting, high stability and large load-bearing capacity.

Matching laser cutting machine, CNC stamping, a variety of CNC processing or other machining deburring edge production line, equipment through linear processing, multiple groups of sand line wheel rotation, revolution, alternating, can truly uniform removal of parts surface, contour edge and hole edge burr and uniform chamfering.

In any cutting, drilling, laser, mill, and other machining processes, burrs, hot slag, and scum will be produced at the edge of the workpiece, so it is particularly important to choose the correct deburring machine.

Video

Application

The application scope of the equipment: It is suitable for flat panel parts, carbon steel plates, stainless steel plates, aluminum plates, copper plates, titanium alloys, various non-ferrous metals, rubber and plastic materials, etc.