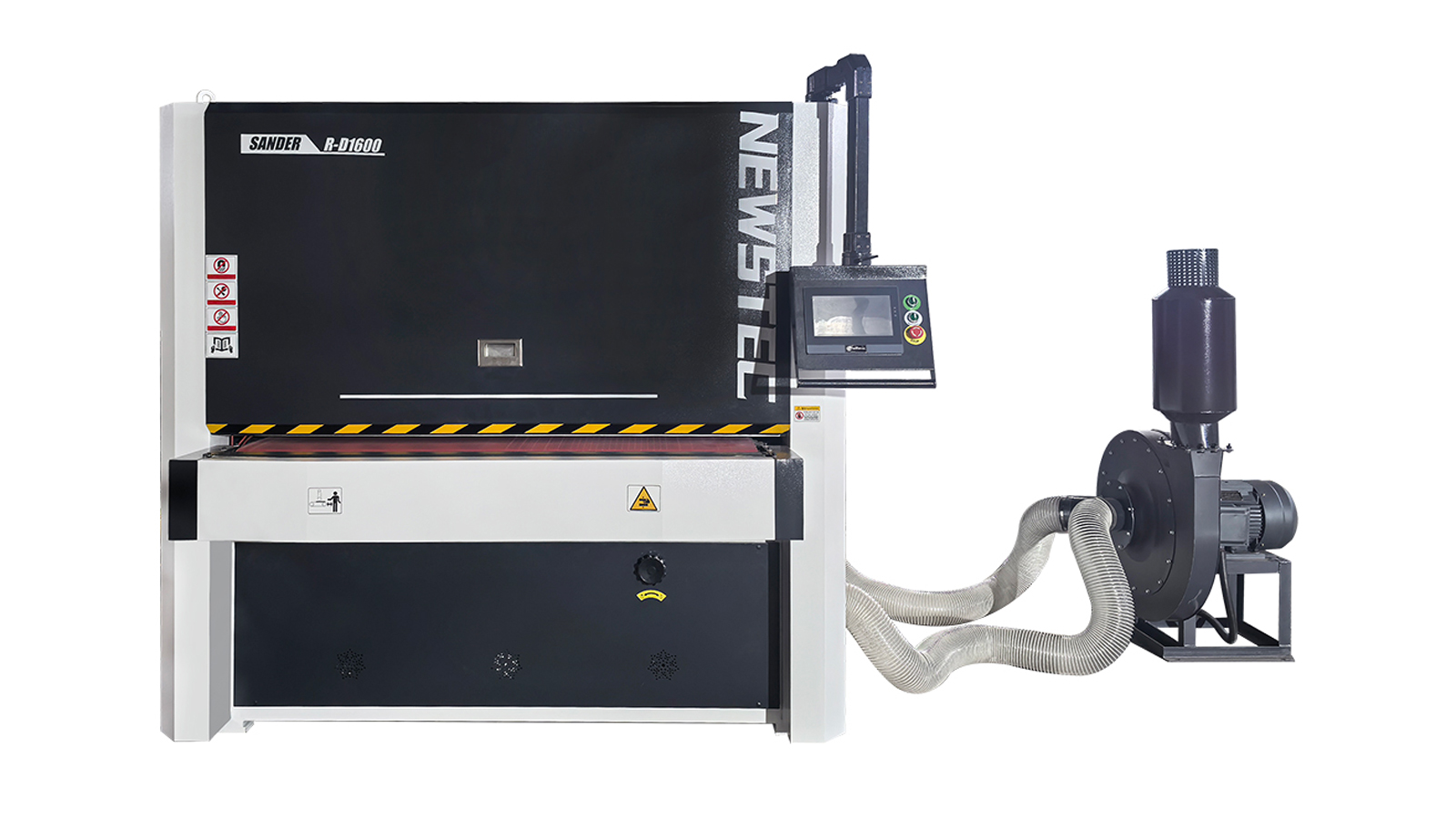

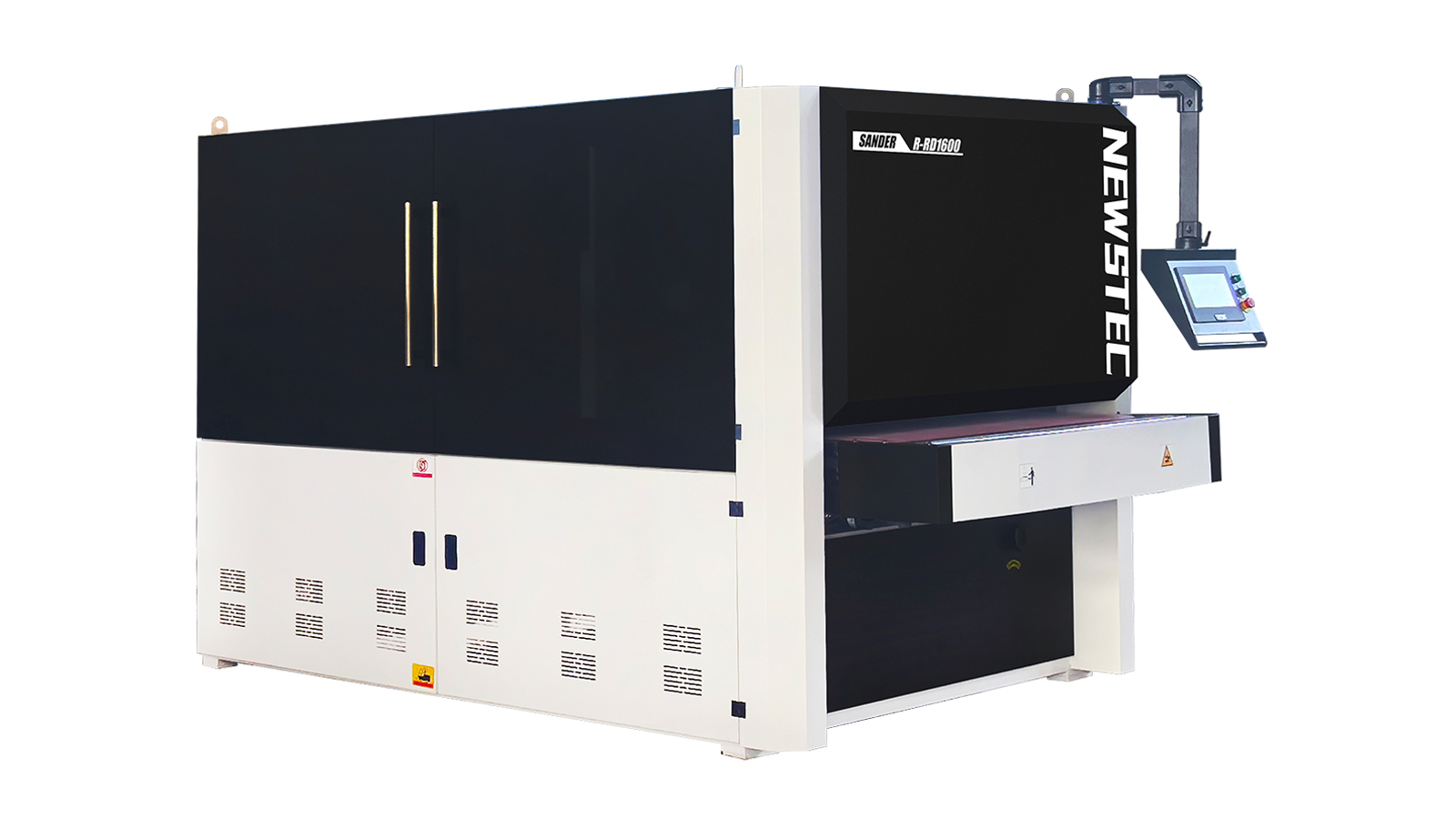

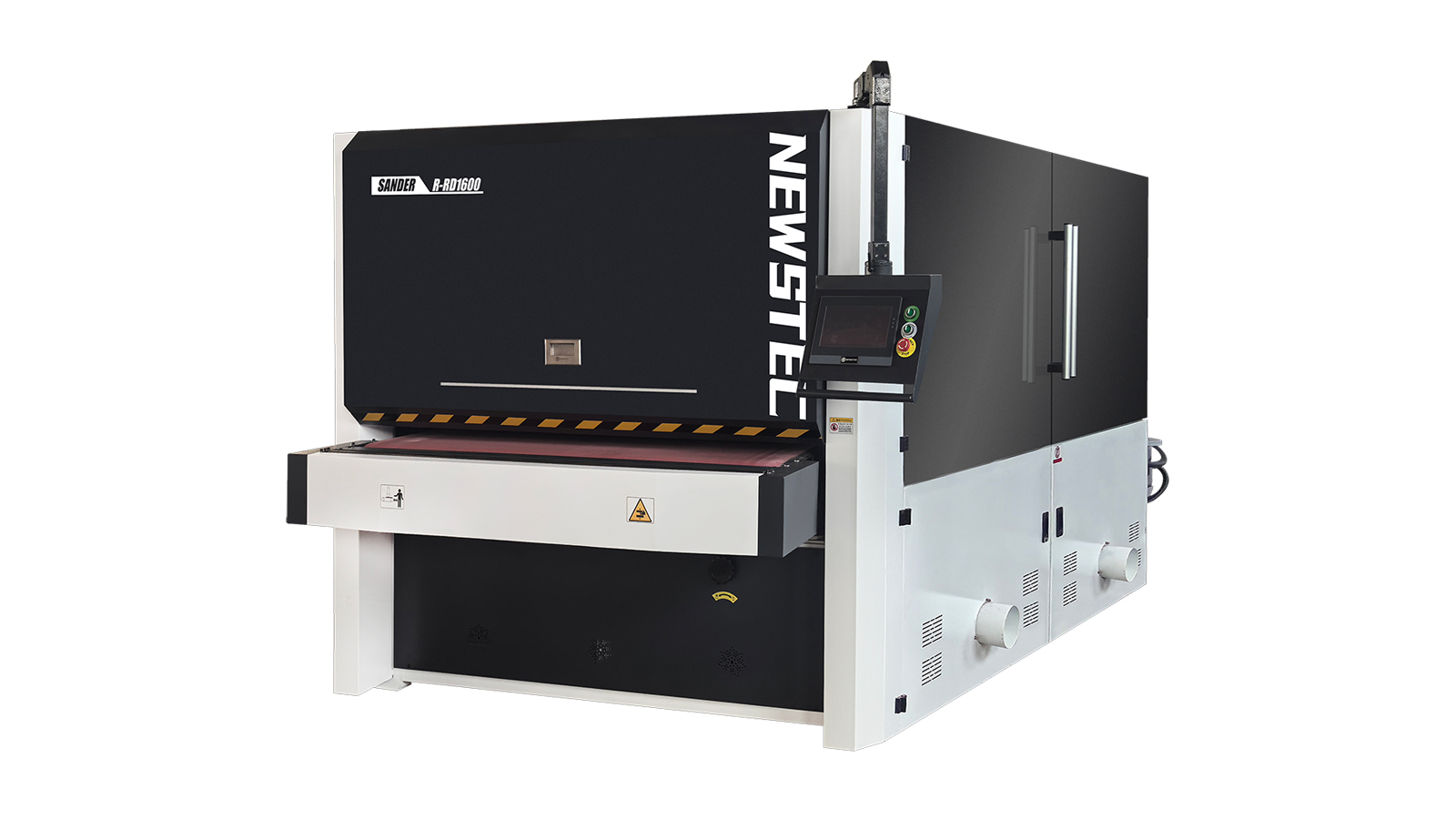

1600mm Automatic Metal Deburring Machine

01020304

Parameters

| Working width(mm) | 1600 |

| Min.Working length(mm) | 300 |

| Working thickness(mm) | 0-100 |

| Abrasive belt motor(kw) | 18.5 |

| Rotary brush motor power(kw) | 2.2X3 |

| Total Power | 44kw |

| Transmission motor power(kw) | 4 |

| Lift motor power | 0.55 |

| No.1 unit of belt shelf | 210mm |

| Adsorption | 11kw 2900RPM |

| Controller system | Delta PLC |

| Rotary brush size(mm) | 300x300x25 |

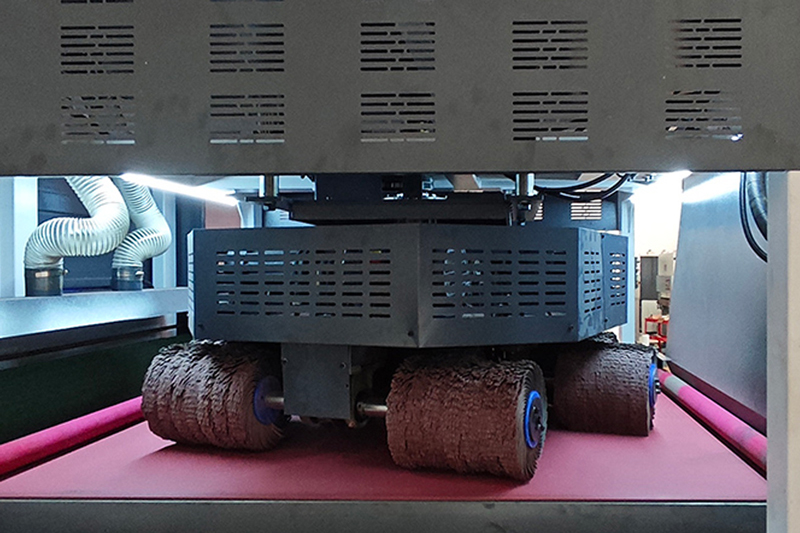

| Rotary brush quantity | 6 |

| Voltage | 220v/380V3PH |

| Power | 50/60HZ |

| Abrasive belt size(mm) | 1320*2020mm |

| Overall dimensions(mm) | Machine :2700*2300*2100mm Vacuum pump :1000*1000*2000mm |

| Gross Weight(with wooden case)(kg) | 3200KGS |

product description

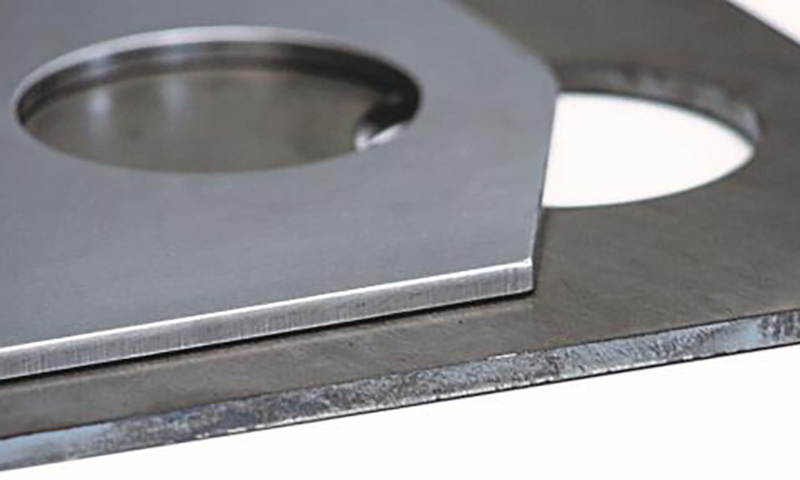

The emergence of metal sheet deburring and chamfering machines has effectively solved these problems.

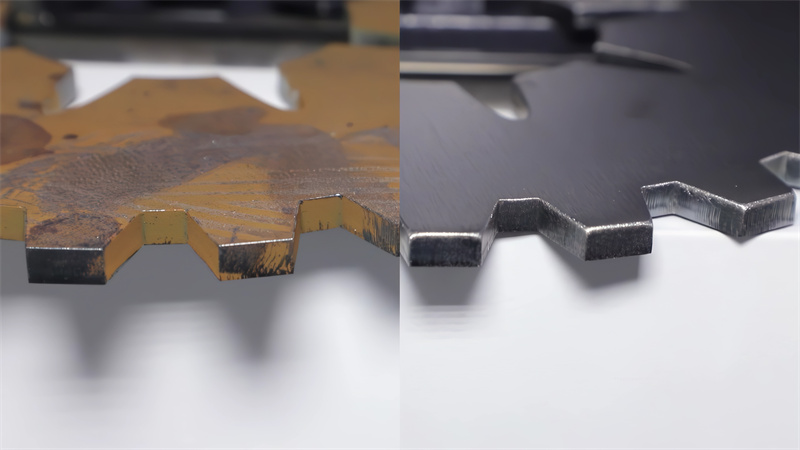

The equipment uses advanced grinding technology to efficiently grind the edges of the sheets through high-speed rotating sanding belts, grinding rollers and other components.

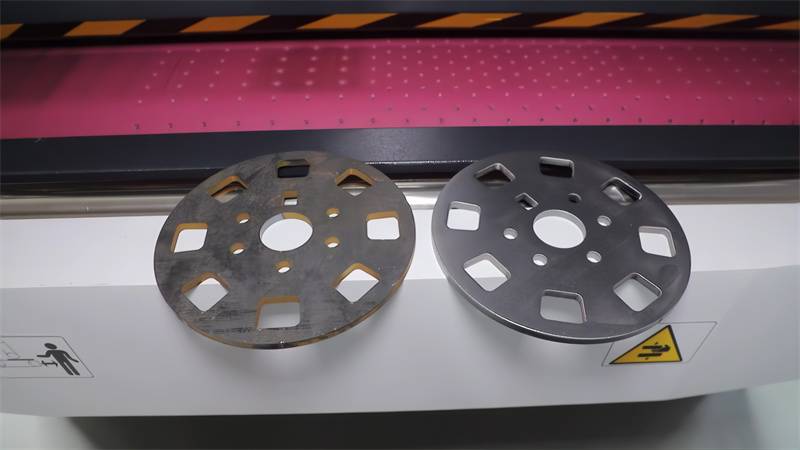

When dealing with burrs generated by laser cutting, stamping, shearing and other processing methods, it can be accurately removed to ensure smooth and flat edges.

For example, for metal sheets with a thickness of 0.5mm - 100mm and a width of less than 1600mm, it can be easily handled.

Its chamfering function is also excellent. According to needs, various angles of chamfers can be formed on the edges of the sheets to meet the process requirements of welding, assembly and other industries in different industries. For example, in industries such as steel structures and shipbuilding, standard and smooth chamfers can significantly improve welding quality.

In terms of operation, the metal sheet deburring and chamfering machine is extremely convenient. Equipped with a touch screen friendly operation interface, workers can quickly get started and accurately set parameters. Moreover, the LED light source inside the equipment makes it easy for operators to observe the processing status.

Its efficient and clean processing characteristics allow the workpiece to directly enter the subsequent folding, surface spraying, welding and other processes, greatly saving time and labor costs, and is an indispensable assistant for metal sheet processing.

-

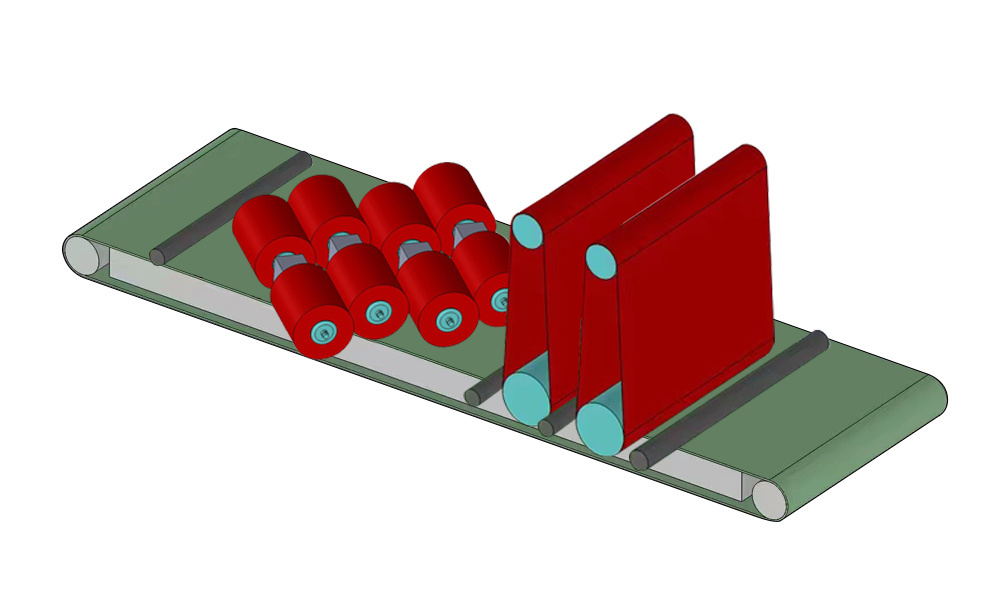

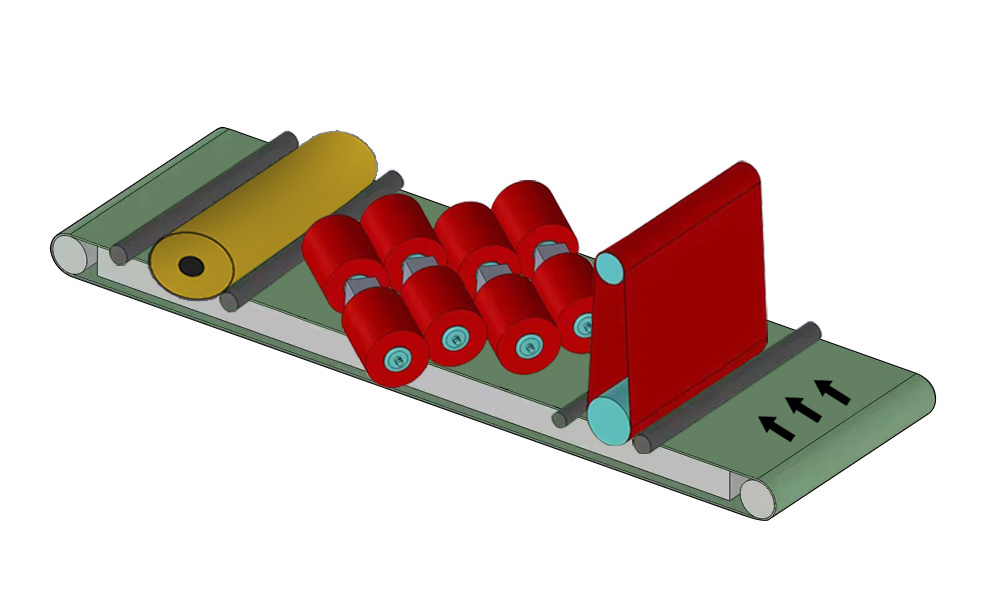

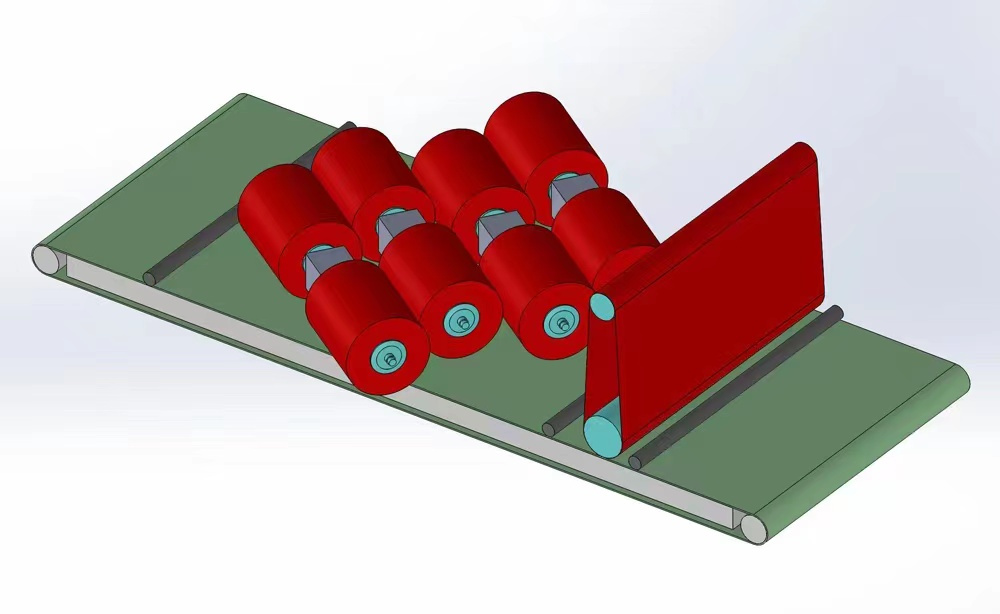

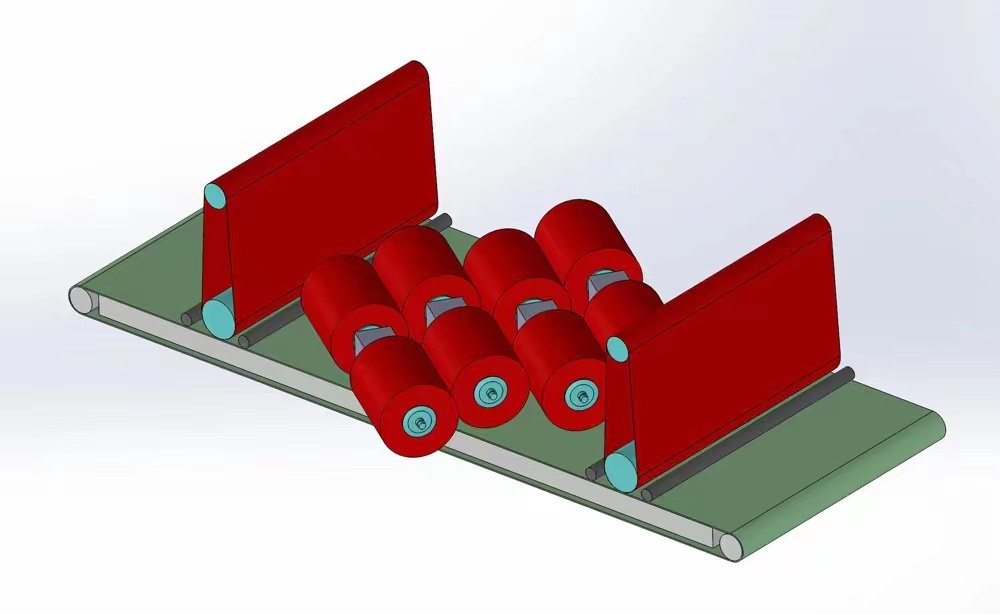

UNIT STRUCTURE

Each unit is independently controlled and can be combined as needed.

-

ROTARY

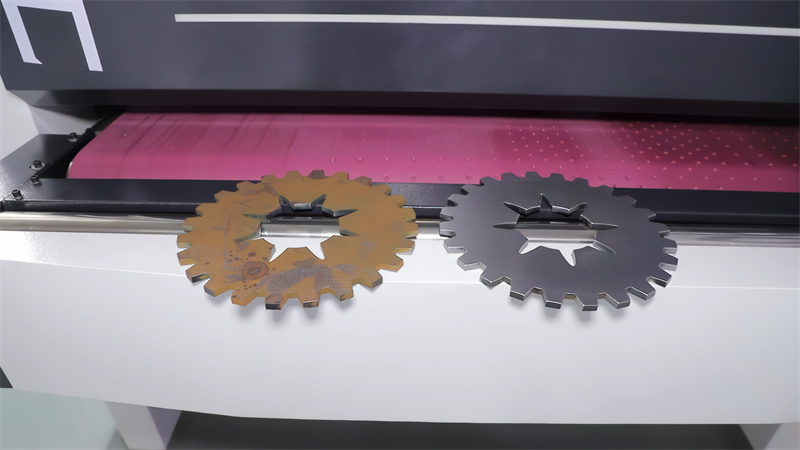

Deburring, chamfering and finishing of internal and external contours.

-

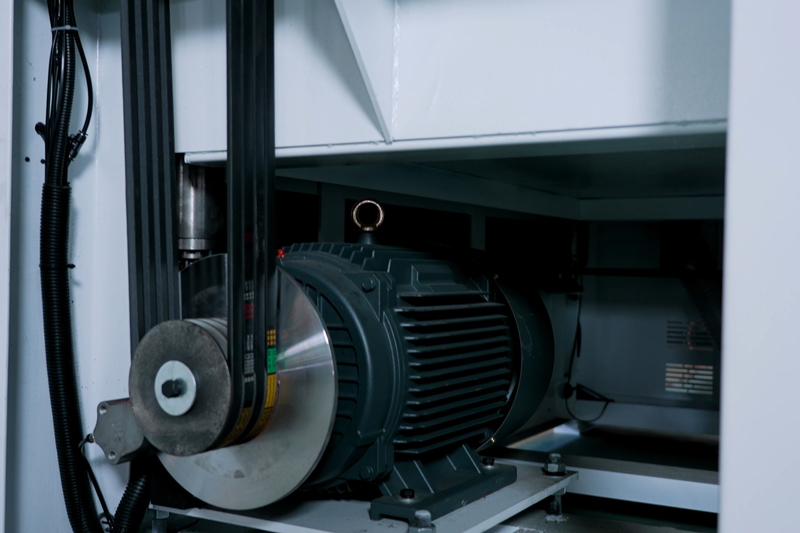

MOTOR

Copper core motor, stable and durable, long service Ife.

-

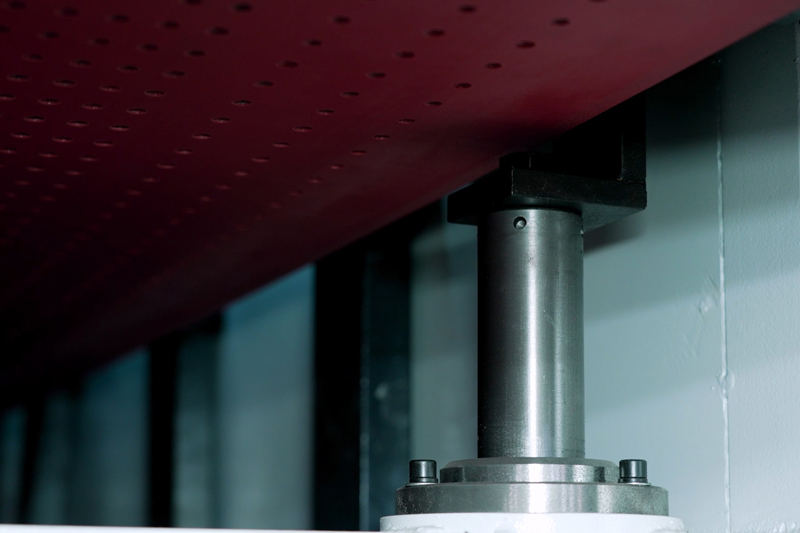

PLATFORM LIFTING

0-100mm lifting platform precise lifting, high stability and large load-bearing capacity.

Matching laser cutting machine, CNC stamping, a variety of CNC processing or other machining deburring edge production line, equipment through linear processing, multiple groups of sand line wheel rotation, revolution, alternating, can truly uniform removal of parts surface, contour edge and hole edge burr and uniform chamfering.

In any cutting, drilling, laser, mill, and other machining processes, burrs, hot slag, and scum will be produced at the edge of the workpiece, so it is particularly important to choose the correct deburring machine.

Video

Application

The application scope of the equipment: It is suitable for flat panel parts, carbon steel plates, stainless steel plates, aluminum plates, copper plates, titanium alloys, various non-ferrous metals, rubber and plastic materials, etc.