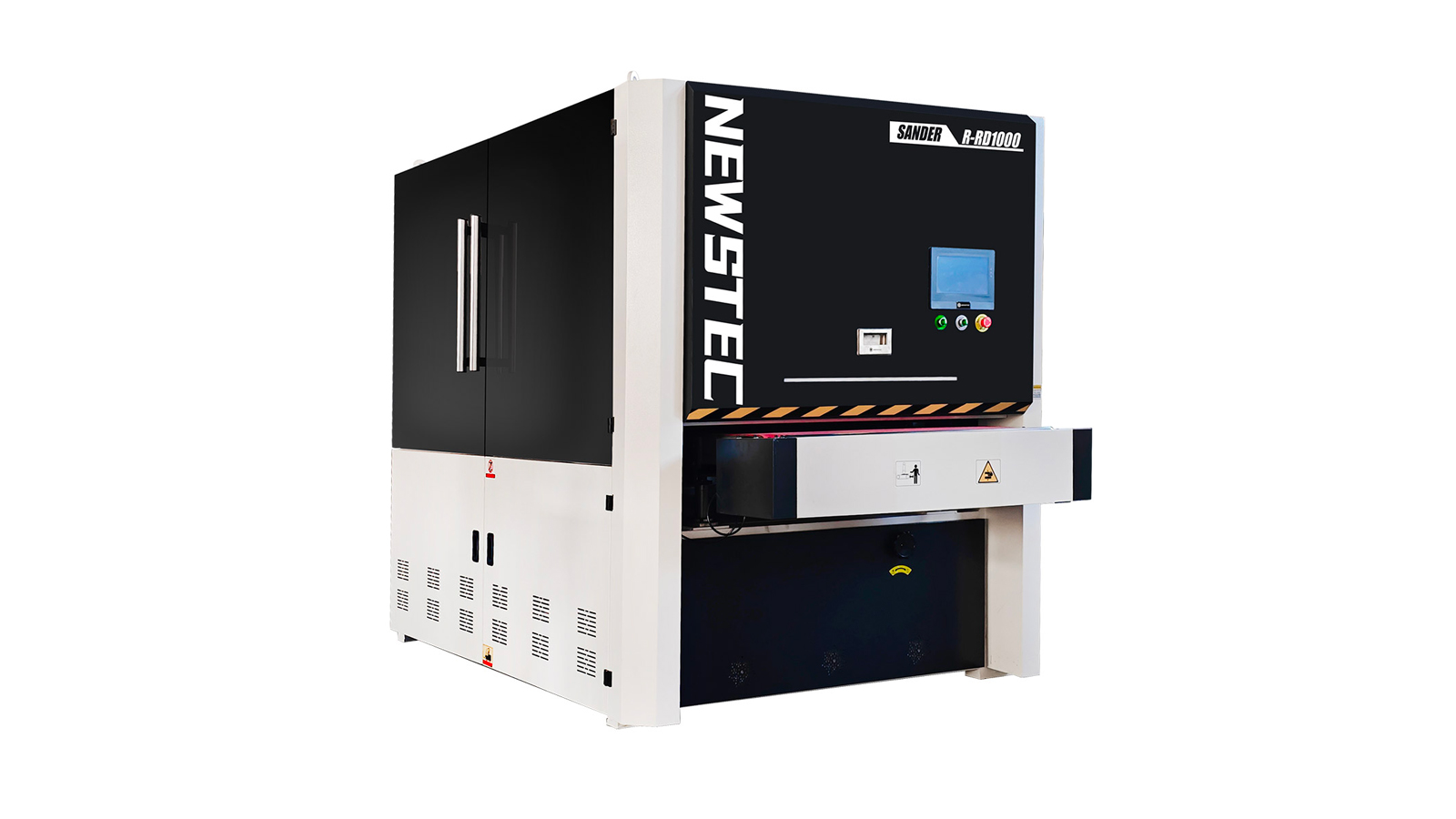

1000mm Automatic Metal Deburring And Chamfering Machine

01020304

Parameters

| Working width(mm) | 800 |

| Min.Working length(mm) | 300 |

| Working thickness(mm) | 0-100 |

| Abrasive belt motor(kw) | 18.5 |

| Rotary brush motor power(kw) | 2.2X3 |

| Total Power | 44kw |

| Transmission motor power(kw) | 4 |

| Lift motor power | 0.55 |

| No.1 unit of belt shelf | 210mm |

| Adsorption | 11kw 2900RPM |

| Controller system | Delta PLC |

| Rotary brush size(mm) | 300x300x25 |

| Rotary brush quantity | 6 |

| Voltage | 220v/380V3PH |

| Power | 50/60HZ |

| Abrasive belt size(mm) | 800*2000mm |

| Overall dimensions(mm) | Machine :2700*1500*2000mm Vacuum pump :1000*1000*2000mm |

| Gross Weight(with wooden case)(kg) | 3200KGS |

product description

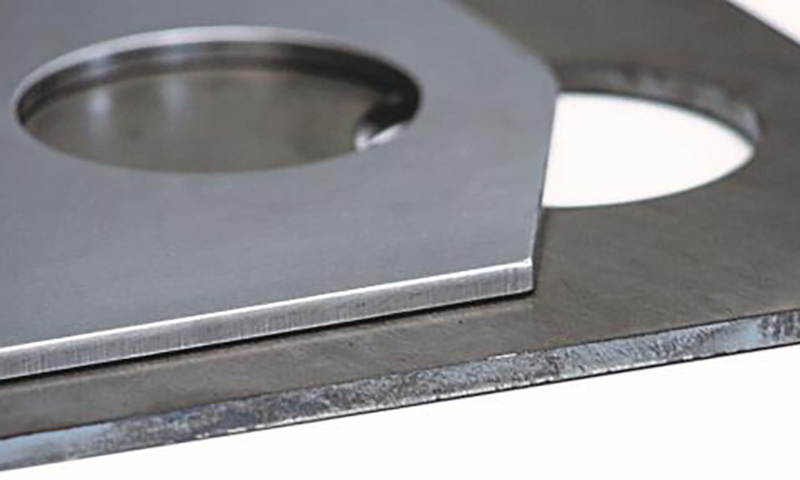

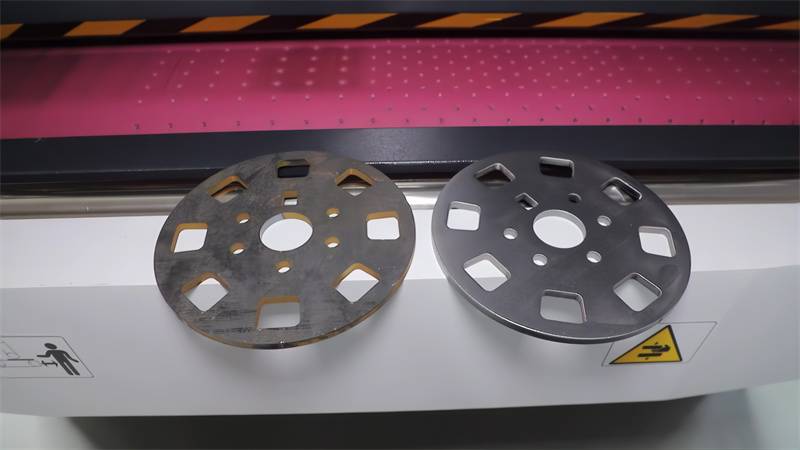

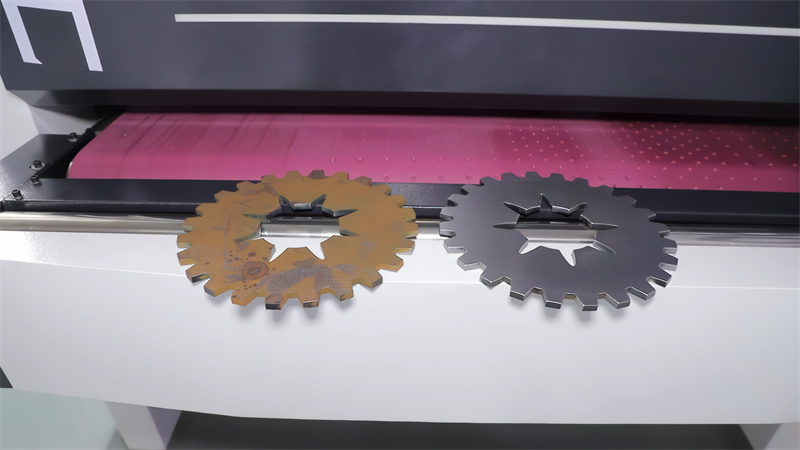

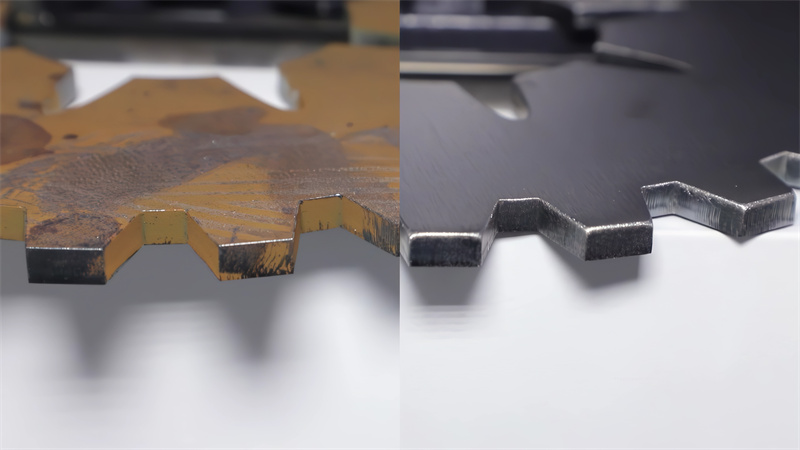

The core advantage of this equipment lies in its precise edge processing capabilities. It uses a combination of multiple high-speed rotating grinding heads, including abrasive belts, wire wheels and grinding wheels, which can be used to remove slag burrs from laser cutting, flash burrs from stamping, and tear burrs from shearing. It is suitable for plates of different materials such as carbon steel, stainless steel, and aluminum alloy.

Application products: Removal of burrs on laser-cut, waterjet-cut and punched products.

Application Industries: Metal deburring machines are widely used in manufacture Billboard.

Signs, Advertising, Signage, Metal Letters, LED Letters, Kitchen Ware, Advertising Letters.

Sheet Metal Processing, Metals Components and Parts, Ironware, Chassis,Racks & Cabinets Processing.

Metal crafts, metal art ware, elevator panel, hardware, auto parts, Glasses Frame, Electronic Parts,Nameplates, etc.

-

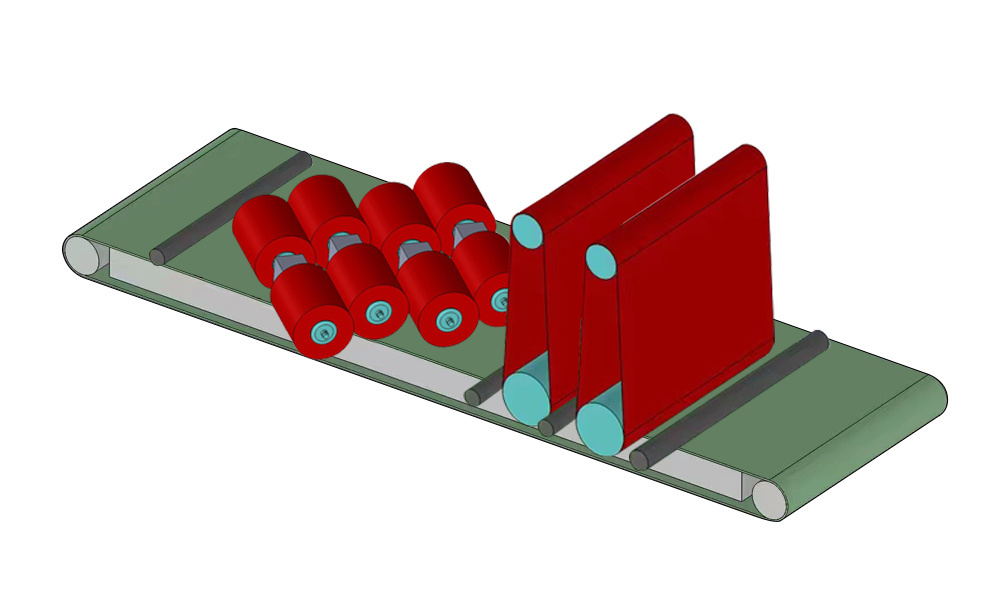

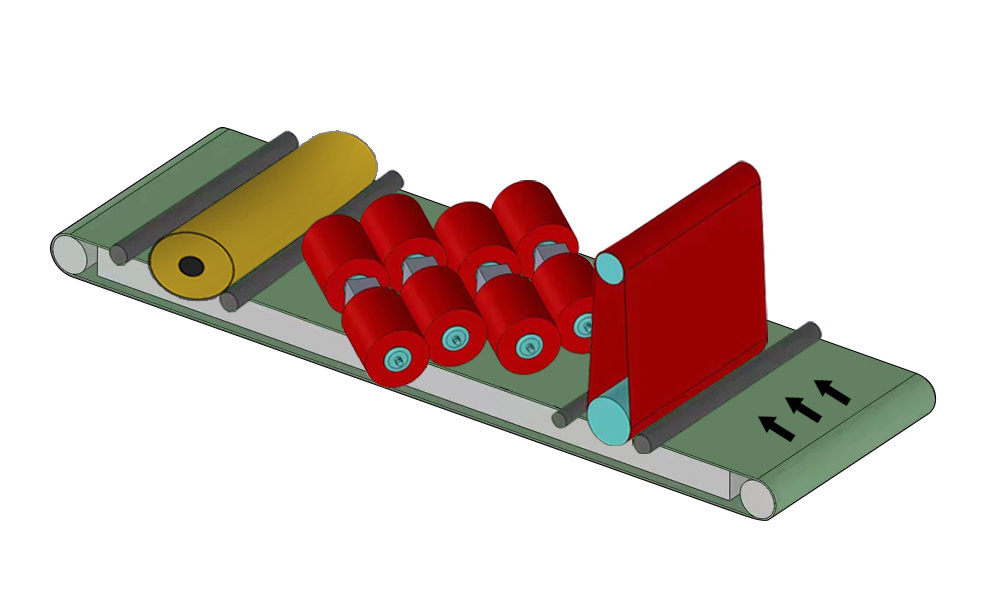

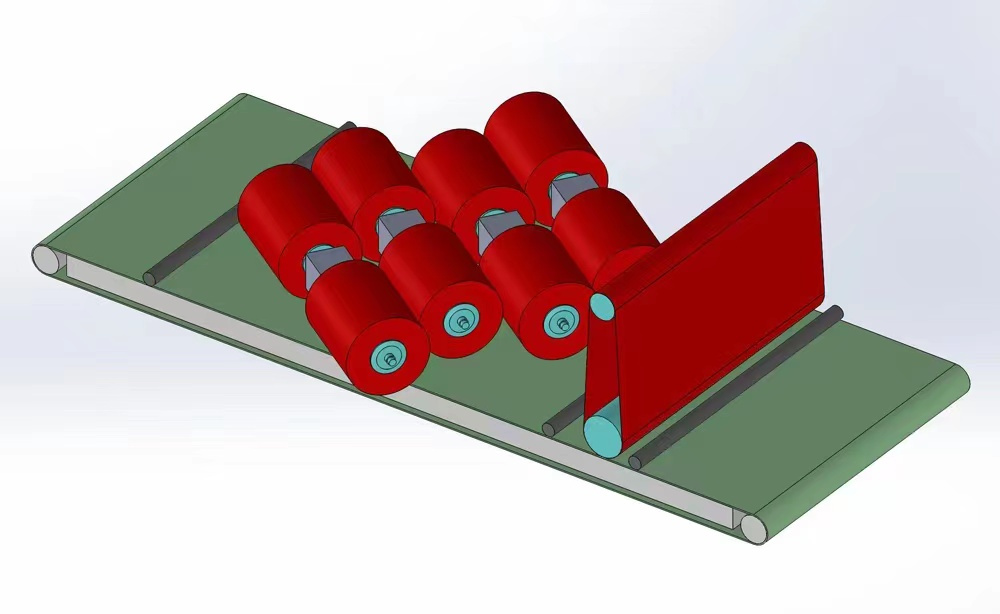

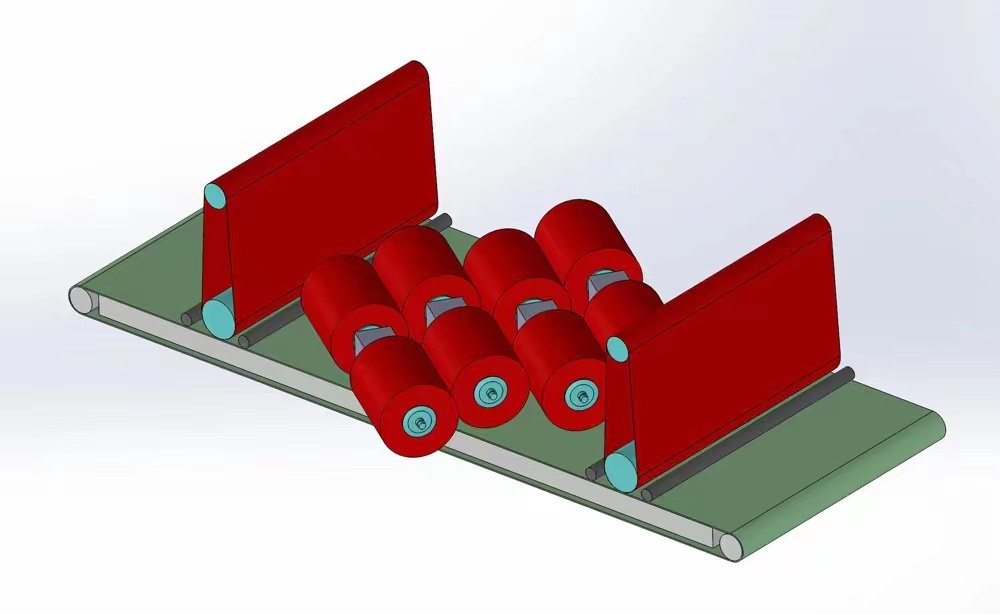

UNIT STRUCTURE

Each unit is independently controlled and can be combined as needed.

-

ROTARY

Deburring, chamfering and finishing of internal and external contours.

-

MOTOR

Copper core motor, stable and durable, long service Ife.

-

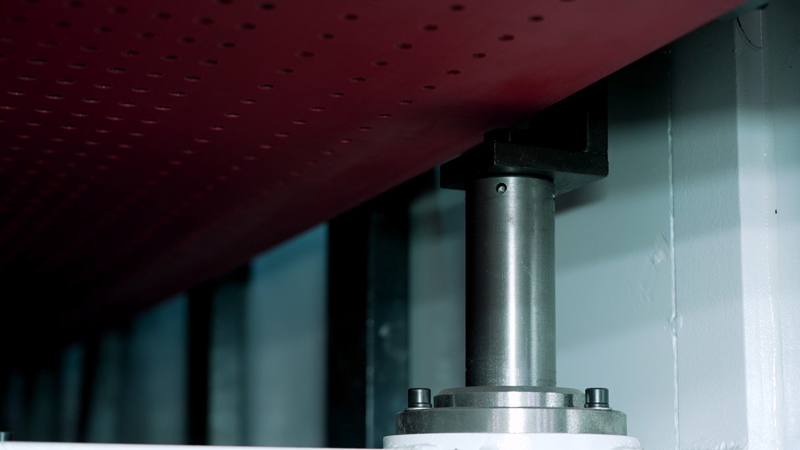

PLATFORM LIFTING

0-100mm lifting platform precise lifting, high stability and large load-bearing capacity.

Matching laser cutting machine, CNC stamping, a variety of CNC processing or other machining deburring edge production line, equipment through linear processing, multiple groups of sand line wheel rotation, revolution, alternating, can truly uniform removal of parts surface, contour edge and hole edge burr and uniform chamfering.

In any cutting, drilling, laser, mill, and other machining processes, burrs, hot slag, and scum will be produced at the edge of the workpiece, so it is particularly important to choose the correct deburring machine.

Video

Application

The application scope of the equipment: It is suitable for flat panel parts, carbon steel plates, stainless steel plates, aluminum plates, copper plates, titanium alloys, various non-ferrous metals, rubber and plastic materials, etc.